In modern data centers, effective cooling solutions are essential to maintain server performance and energy efficiency. Liquid cooling has emerged as a superior alternative to traditional air cooling, ensuring optimal thermal management.

A critical component of liquid cooling systems is precision-drilled pipelines, which require high accuracy and reliability to ensure smooth coolant flow. This is where CNC drilling machines play a crucial role.

This article explores the importance of CNC drilling machines for liquid cooling pipelines, their technology, advantages, applications, and future trends, making it an essential resource for manufacturers, engineers, and data center operators.

1. Why Liquid Cooling is Essential for Data Centers

1.1 The Growing Need for Efficient Cooling

With the rapid expansion of high-density computing, including AI, cloud computing, and edge computing, the demand for efficient cooling is higher than ever. Liquid cooling offers a more effective heat dissipation solution, reducing power consumption and carbon footprint.

1.2 The Role of CNC-Drilled Pipelines in Liquid Cooling

Uniform Coolant Flow: Precision-drilled pipelines ensure consistent temperature regulation.

Leak Prevention: Properly drilled holes prevent fluid leaks and pressure drops.

Optimal Heat Transfer: CNC drilling guarantees smooth interior surfaces, reducing friction and improving thermal performance.

2. CNC Drilling Machines for Liquid Cooling Pipelines

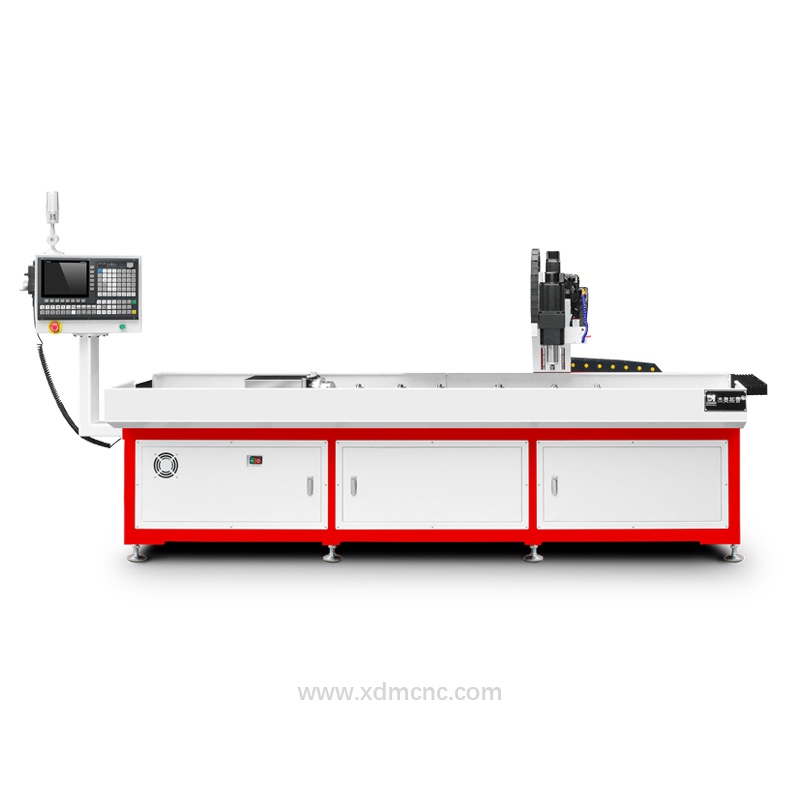

2.1 What is a CNC Drilling Machine?

A CNC (Computer Numerical Control) drilling machine is an advanced automated drilling system that ensures:

✔ High precision and accuracy

✔ Consistent hole placement and depth

✔ Automated multi-axis movement for complex shapes

✔ Fast and efficient mass production

2.2 Key Features of CNC Drilling for Liquid Cooling Pipes

High-Speed Drilling: Reduces production time and increases efficiency.

Multi-Axis Capability: Enables drilling at various angles for complex cooling designs.

Material Versatility: Works with copper, stainless steel, and aluminum.

Real-Time Quality Control: Uses sensors and AI for defect detection.

3. Benefits of Using CNC Drilling Machines for Liquid Cooling Pipelines

3.1 Unmatched Accuracy and Consistency

CNC machines ensure precise hole alignment, reducing errors that could cause leakage or uneven cooling.

3.2 Higher Productivity and Cost Efficiency

Automated operation reduces labor costs.

Faster drilling speeds improve production output.

3.3 Reduced Material Waste

CNC precision minimizes misalignment and scrap materials.

Real-time adjustments prevent over-drilling and defects.

3.4 Compatibility with Different Pipe Materials

CNC machines efficiently drill:

✔ Copper pipes – Best thermal conductivity

✔ Aluminum pipes – Lightweight and cost-effective

✔ Stainless steel pipes – Corrosion-resistant and durable

3.5 Smart Manufacturing & IoT Integration

Modern CNC drilling machines support Industry 4.0, featuring:

AI-powered optimization for tool paths

IoT connectivity for real-time monitoring

Predictive maintenance to reduce downtime

4. Applications of CNC Drilling in Liquid Cooling Systems

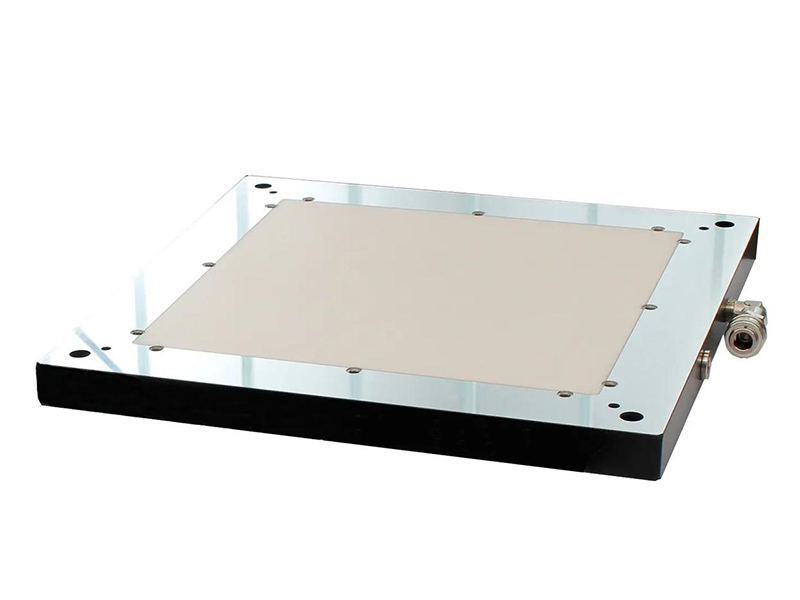

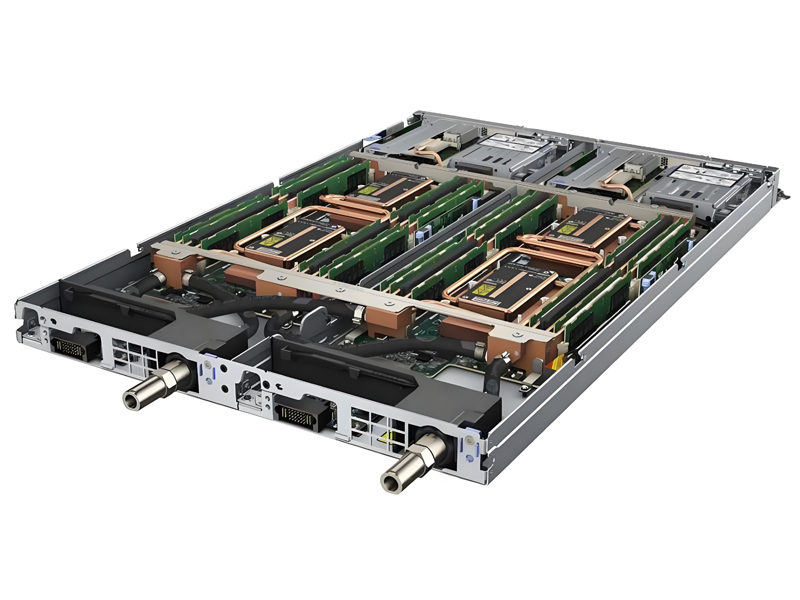

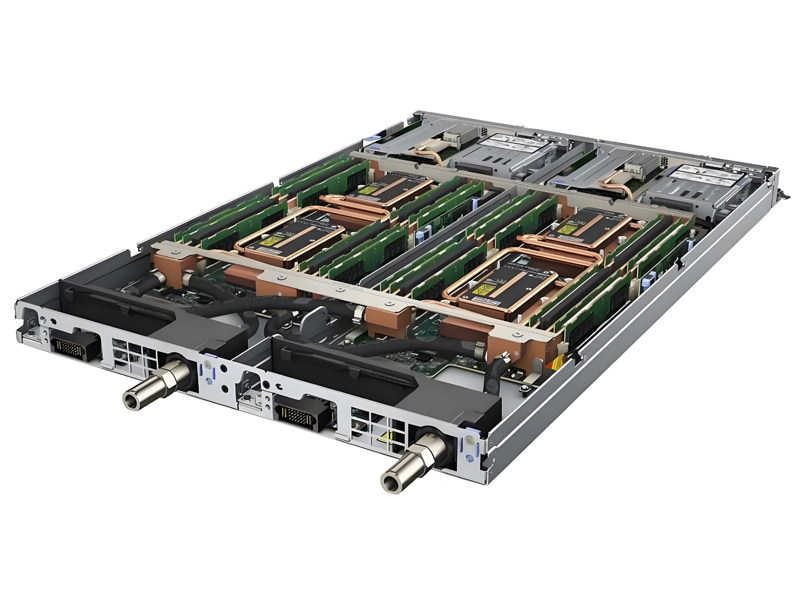

4.1 Server Rack Cooling Pipelines

Precisely drilled pipes distribute coolant evenly across servers.

Reduces overheating and improves system reliability.

4.2 Heat Exchanger Tube Processing

Ensures optimal thermal exchange efficiency.

Prevents fluid turbulence and pressure losses.

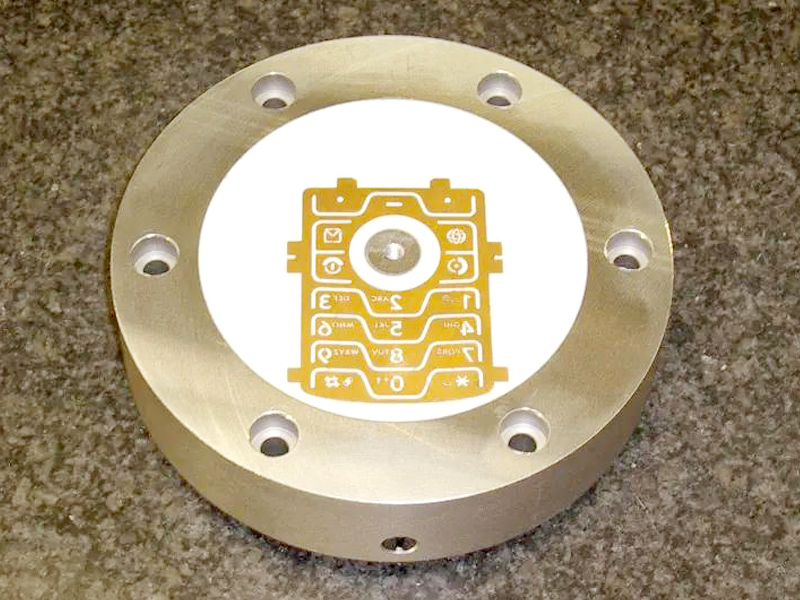

4.3 Custom Manifold Manufacturing

Drilled manifolds allow precise coolant distribution.

Supports high-density server cooling applications.

4.4 Data Center Coolant Distribution Networks

Large pipelines require high-precision hole drilling.

CNC drilling ensures long-term reliability in large-scale cooling systems.

5. Future Trends in CNC Drilling for Data Center Cooling

5.1 AI & Automation in CNC Drilling

✔ AI-driven toolpath optimization improves efficiency.

✔ Automated robotic arms enhance precision and speed.

5.2 Hybrid Manufacturing (CNC + 3D Printing)

✔ CNC drilling + additive manufacturing enables complex coolant channel designs.

✔ Reduces material waste and improves part customization.

5.3 Sustainable Manufacturing & Energy Efficiency

✔ Eco-friendly coolants and lubricants reduce environmental impact.

✔ Low-power CNC machines help cut energy costs.

5.4 Advanced Materials for Liquid Cooling Pipes

✔ Nanocoated surfaces improve heat transfer efficiency.

✔ Next-gen alloys offer higher durability and corrosion resistance.

6. Conclusion

The future of data center cooling depends on precision-engineered liquid cooling pipelines, and CNC drilling machines are at the heart of this transformation.

Investing in high-precision CNC drilling technology allows manufacturers, engineers, and data center operators to achieve:

✅ Higher efficiency in cooling system manufacturing

✅ Lower operational costs with automated precision drilling

✅ Improved sustainability through eco-friendly CNC processes

For companies seeking to enhance data center cooling performance, adopting CNC drilling solutions is a game-changer.

keywords: CNC drilling machine, liquid cooling pipelines, data center cooling, precision drilling, smart manufacturing, Industry 4.0