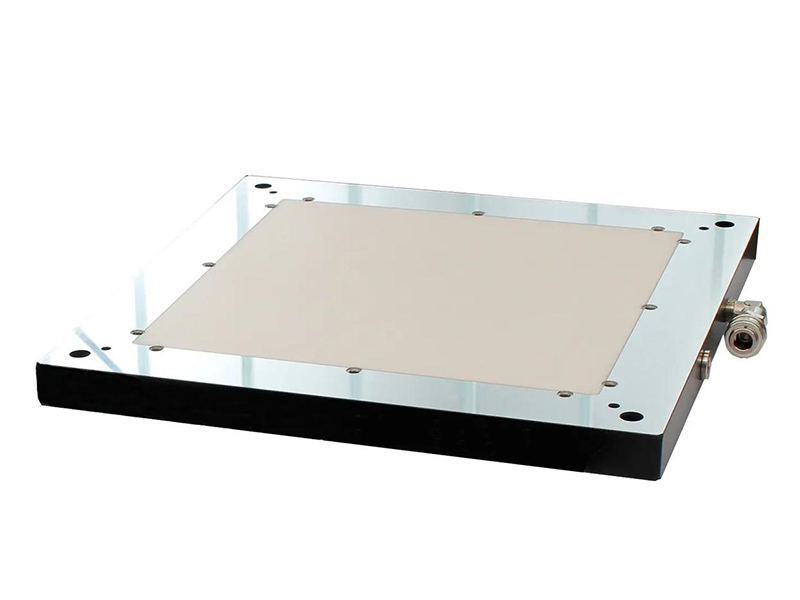

In the semiconductor industry, the use of CNC drilling for perforated boards is becoming increasingly widespread. The PC&MA series perforated boards, with their excellent performance, have become the ideal choice for non-metallic clamping devices. These boards are not only easy to process and have smooth surfaces but also have a high-temperature resistance of up to 108°C, with hole diameters as small as 30µm, making them particularly suitable for clamping devices in semiconductor industry applications.

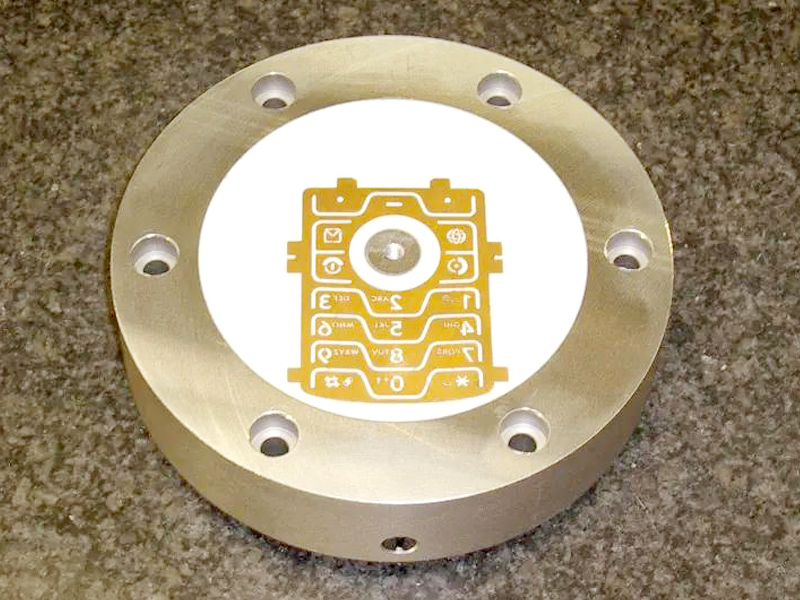

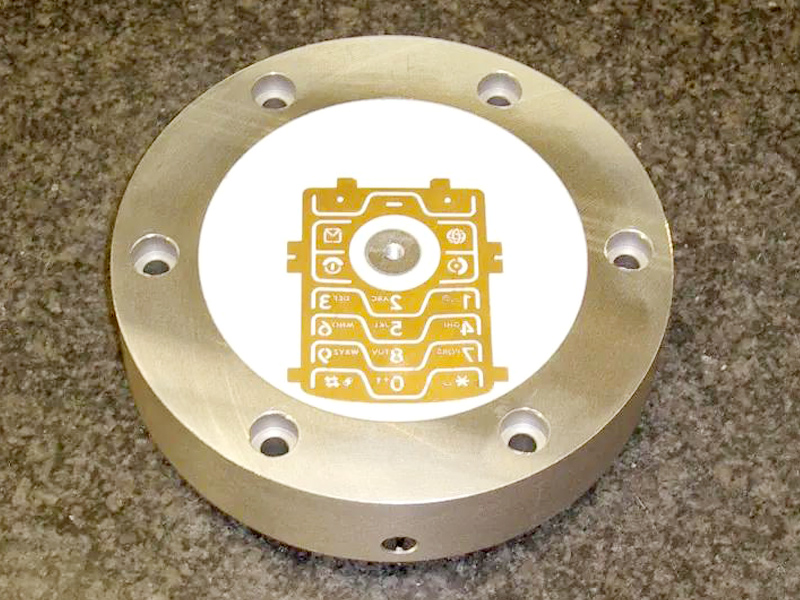

Vacuum suction cup after CNC drilling

CNC drilling vacuum suction cups have widespread applications in the microelectronics industry, such as wafer processing, IC assembly, chip and wire bonding, and more. The micro-hole ceramic working plates made from PC100 board blanks are specialized tools used in the semiconductor wafer production process, suitable for thinning, cutting, grinding, cleaning, and handling. These working plates can achieve a surface flatness of up to 5µm.

The CNC drilling vacuum suction cup, MA100, is a unique black micro-perforated product designed for applications requiring completely dark surfaces without reflections. This porous material retains its black color even after milling and can be used for vacuum suction cups in 3D and optical measurement equipment or for quality inspection of transparent RFID foils. Like other products, it can precisely clamp workpieces with extremely high flatness requirements without deformation. Even when partially covered, it provides stable clamping force.

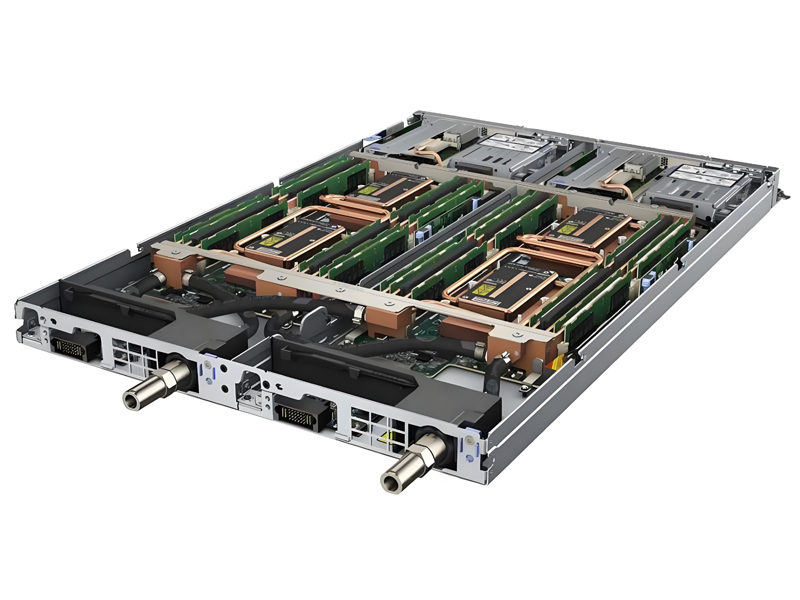

Additionally, these perforated boards are widely used in pneumatic transport or vacuum forming positioning applications. The material is typically transported on rollers or belts and is used to non-contact transport sensitive materials such as semiconductor wafers, glass substrates, specialty foils, and flat-panel displays through air cushions.