In the semiconductor industry, the combination of vacuum suction cups and CNC drilling is a key innovation for enhancing precision and efficiency in various applications. Vacuum suction cups, when integrated with CNC drilling, provide a reliable and precise method of clamping and handling sensitive semiconductor materials, ensuring high-quality processing and reducing the risk of damage to delicate components.

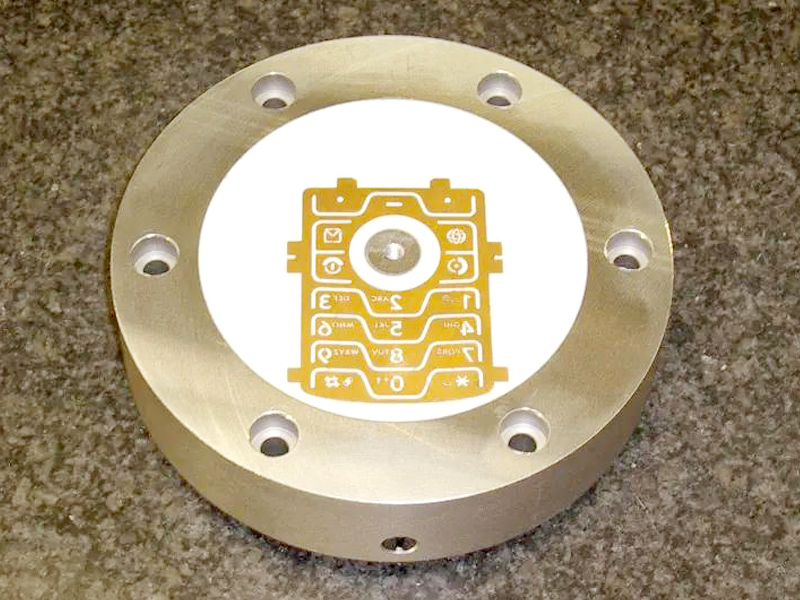

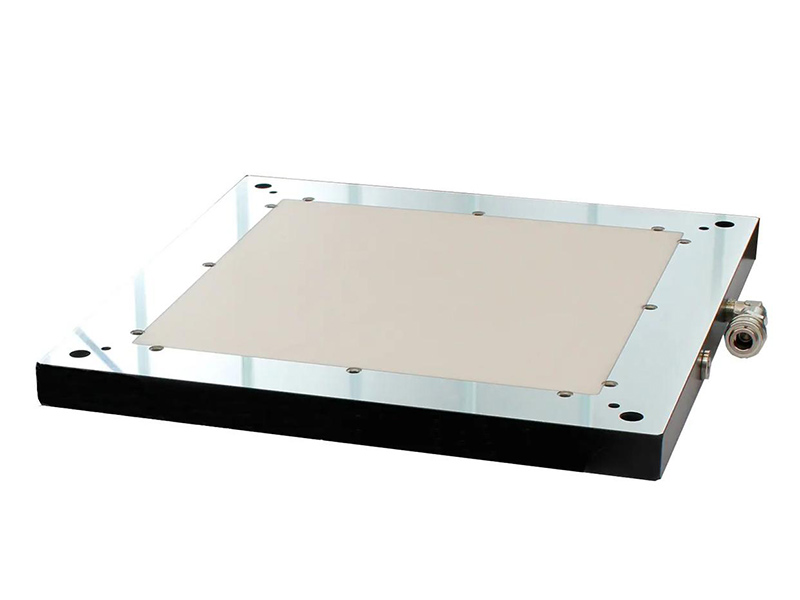

CNC drilling of vacuum suction cup

Key Applications:

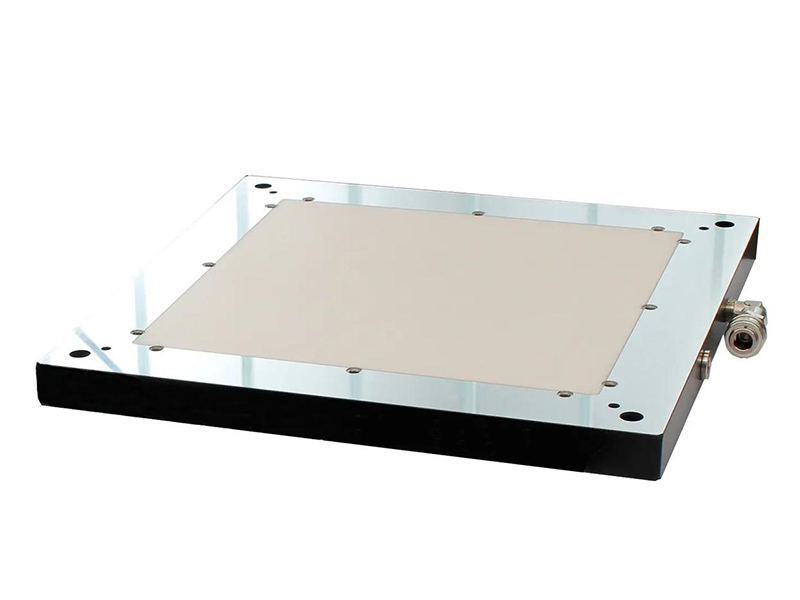

1. Wafer Processing and Handling

In semiconductor wafer processing, vacuum suction cups are used to hold wafers in place while CNC drilling machines perform high-precision drilling tasks. The precise clamping ensures that the wafer remains stable during the drilling process, which is crucial for maintaining tight tolerances and preventing movement that could lead to defects or reduced yield.

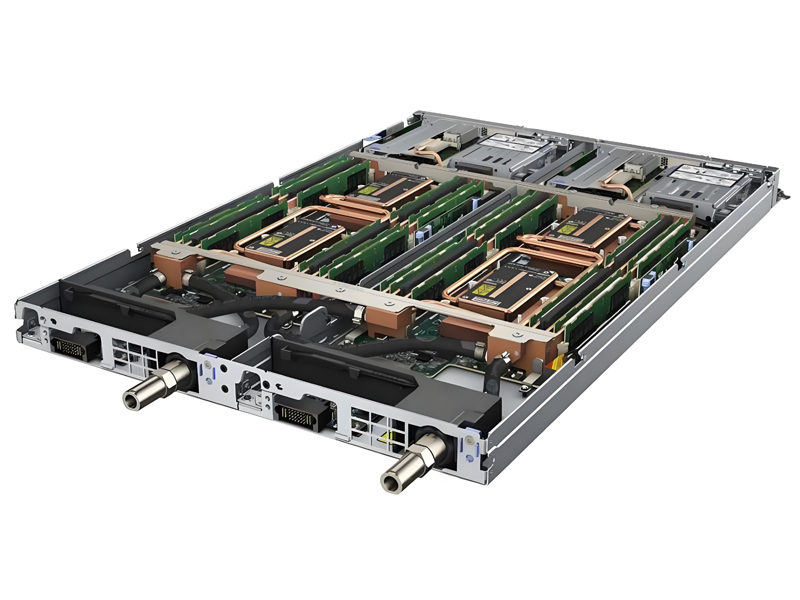

2. Microelectronics Assembly

In the assembly of ICs (integrated circuits) and other microelectronic components, CNC drilling with vacuum suction cups is used to handle and position the components accurately during processes like chip bonding, wire bonding, and packaging. The vacuum suction cups provide strong but gentle clamping to prevent any potential damage to fragile materials while also providing the necessary support for precision drilling.

3. Specialized Tooling

Vacuum suction cups made from perforated materials, like the PC100 or MA100 series, are often used in specialized tooling applications. These suction cups are particularly useful for delicate semiconductor materials such as glass substrates, specialty foils, and flat-panel displays. The vacuum cups provide non-contact handling, which is crucial when transporting sensitive materials through processes like cutting, grinding, and polishing.

Benefits of Vacuum Suction Cup Integration with CNC Drilling:

Precision Clamping: The vacuum suction cups ensure the workpieces remain securely in place during the drilling process, which is essential for achieving high accuracy and precision in semiconductor manufacturing.

No Deformation: The suction cups can handle delicate components without causing deformation, ensuring the integrity of the workpieces.

Non-Contact Handling: The use of vacuum suction cups eliminates the risk of physical contact, reducing the chance of scratches or damage to the sensitive surfaces of semiconductor materials.

Efficient Transport: In conjunction with CNC drilling, the suction cups enable efficient non-contact transport of semiconductor materials, improving the overall efficiency and throughput of the production process.

This combination of vacuum suction cups and CNC drilling is essential for meeting the rigorous demands of the semiconductor industry, where both precision and material integrity are critical.