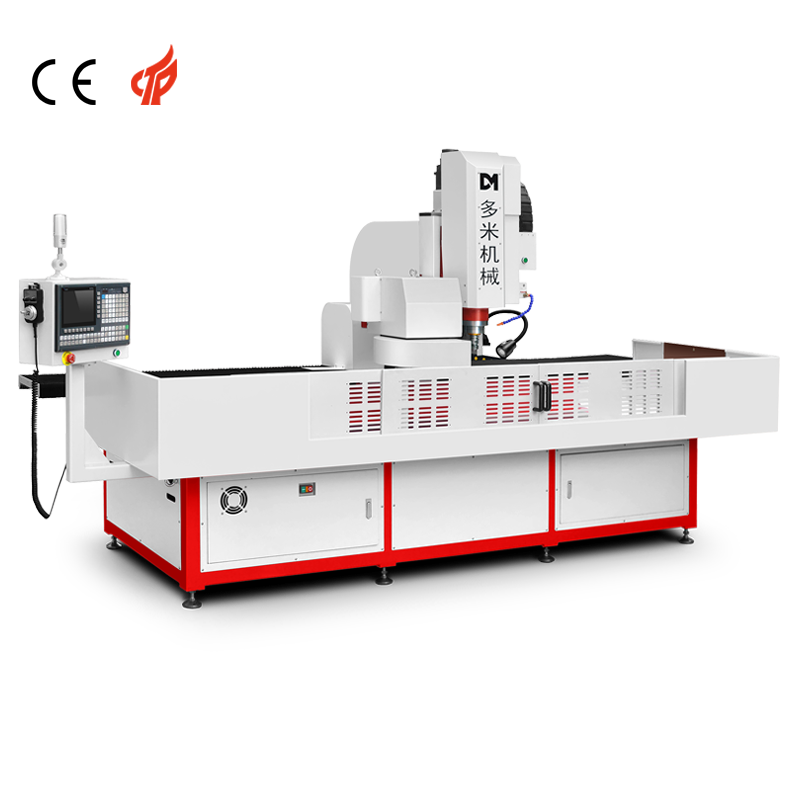

The flow CNC drilling and tapping machine is mainly used in steel companies for drilling, tapping, and thermal forming processes. It integrates CNC technology with flow drilling, making it suitable for processing metal materials such as steel, stainless steel, and aluminum alloys. It is particularly applicable in the following scenarios:

Steel structure processing: Used for drilling and tapping H-beams, square tubes, channel steel, etc., improving processing efficiency and precision.

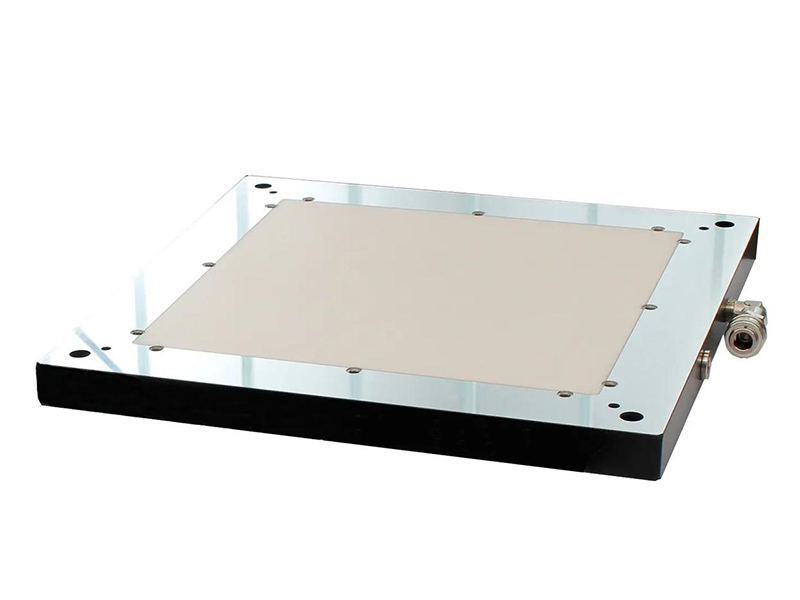

Machinery manufacturing: Suitable for high-precision drilling and tapping of various mechanical components.

Metal products industry: Used for processing metal frames, railings, construction brackets, and more, enhancing automation in production.

Automobile manufacturing: Applied in the precise machining of vehicle frames, chassis, and other components.

Bridge and construction engineering: Used for processing steel beams, connection plates, etc., improving construction quality.

Compared to traditional drilling methods, the flow CNC drilling and tapping machine offers several advantages:

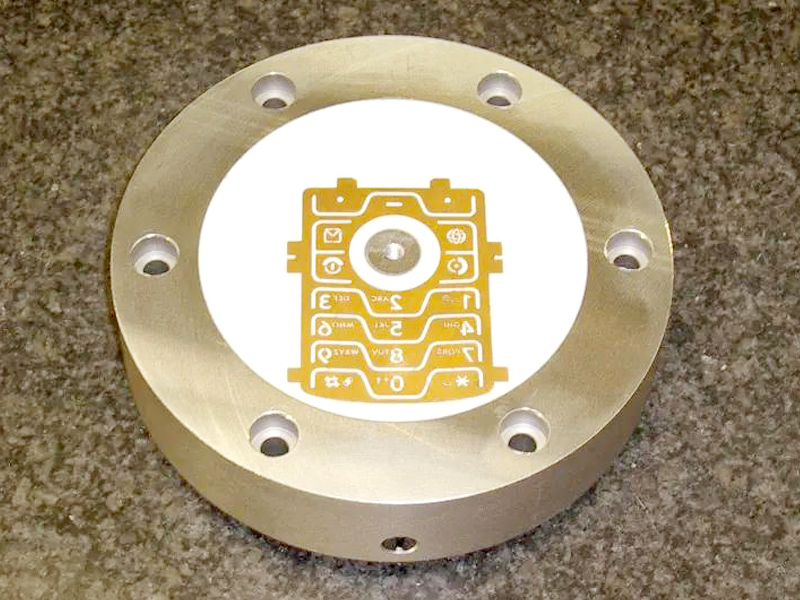

No pre-drilling required: The flow drilling technique allows direct penetration of metal while forming a reinforced hole wall, increasing connection strength.

High efficiency and stability: CNC system control ensures high precision and fast speed, making it ideal for mass production.

Reduced material waste: Minimizes chips and improves material utilization.

If your steel company requires efficient and automated drilling and tapping processes, a flow CNC drilling and tapping machine is a great choice. Would you like to know more details?