Drilling small holes in stainless steel is challenging due to the material's hardness, toughness, and tendency to work-harden. However, with the right techniques, tools, and parameters, it is possible to achieve precision drilling with minimal wear and heat buildup.

Key Challenges in Drilling Small Holes in Stainless Steel:

Work Hardening – Stainless steel quickly hardens when drilled, making subsequent passes more difficult.

High Heat Generation – Stainless steel retains heat, which can damage drill bits and affect hole quality.

Tool Wear – Due to its high toughness, stainless steel can rapidly dull standard drill bits.

Chip Removal – Small holes trap chips, increasing the risk of drill breakage and surface defects.

Recommended Techniques and Solutions

1. Selecting the Right Drill Bit

Carbide or Cobalt Drill Bits – Carbide drill bits offer high hardness and wear resistance, while cobalt drill bits (HSS-Co) are ideal for heat resistance.

Diamond-Coated or TiAlN-Coated Bits – These reduce friction and extend tool life.

Split-Point or Parabolic-Flute Bits – These help with self-centering and chip evacuation, preventing clogging.

2. Proper Drilling Speeds & Feeds

Drilling Speed (RPM): Lower speeds reduce heat buildup.

Small holes (<1 mm): 800–2000 RPM

Medium holes (1–5 mm): 400–1200 RPM

Larger holes (5–10 mm): 200–600 RPM

Feed Rate: Moderate feed pressure prevents work hardening (e.g., 0.02–0.1 mm/rev).

3. Lubrication & Coolant

Cutting Fluids (e.g., oil-based or synthetic lubricants) reduce friction, dissipate heat, and improve hole quality.

Through-Spindle Coolant (if available) helps with micro-hole drilling.

Misting Systems or Flood Cooling can be used for better heat management.

4. Drill Bit Entry and Peck Drilling

Pilot Hole – For holes larger than 3 mm, use a smaller pilot hole (~50% of final size) to reduce tool stress.

Peck Drilling – Lifting the drill after every 0.5–1 mm prevents chips from clogging the hole and reduces heat buildup.

5. Workholding & Stability

Secure Clamping – Reduces vibration and increases precision.

Carbide Bushings or Guides – Help maintain alignment for very small holes.

6. CNC Micro-Drilling Techniques

For ultra-small holes (<0.5 mm), CNC drilling or laser-assisted drilling can be used:

Ultrasonic-Assisted Drilling – Reduces cutting forces and improves accuracy.

Electrochemical or Laser Drilling – Useful for hole diameters below 100 microns.

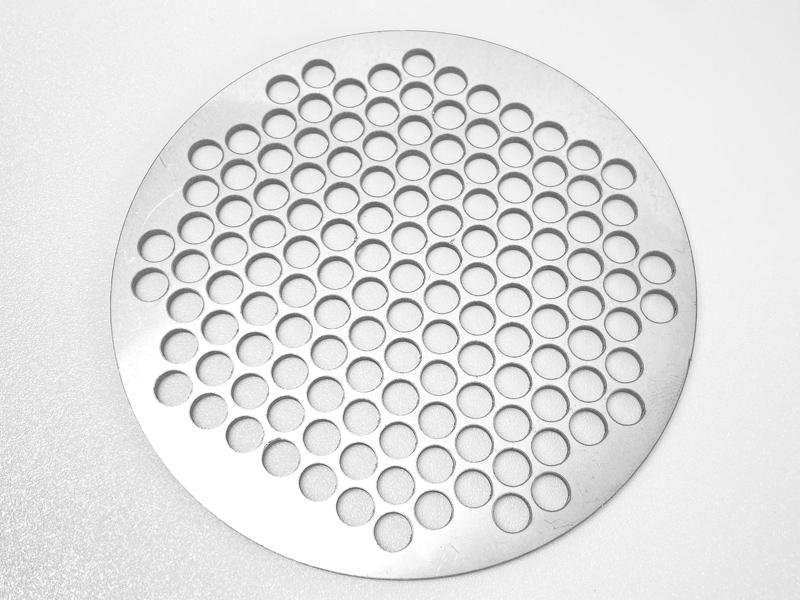

drilling small holes in stainless steel

Drilling small holes in stainless steel requires careful selection of drill bits, optimized speed and feed rates, adequate cooling, and chip management techniques. For precision applications, CNC drilling, ultrasonic, or laser drilling may be necessary to ensure high-quality micro-holes with minimal tool wear.