The machine hums softly as the first stainless steel square tube locks into place. The air smells faintly of coolant and metal — a familiar scent in modern workshops where precision meets innovation.

Then, with a quiet whir, the fully automatic CNC drilling machine comes alive.

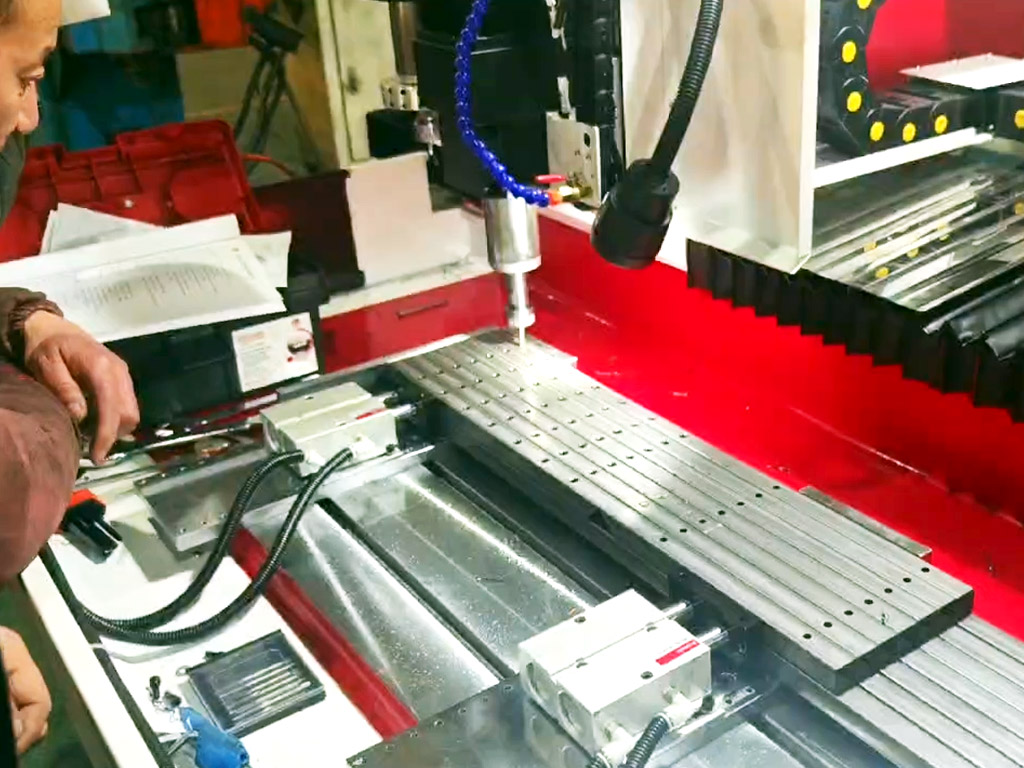

This isn't an ordinary drill press. It's a fully automated system designed to perform multi-hole drilling on stainless steel tubes — quickly, cleanly, and with remarkable accuracy.

The Scene of Precision Engineering

Under the bright white workshop lights, a row of stainless steel tubes gleams on the machine table. Each one has been cut to exact length, waiting for perfectly aligned holes to be drilled along its surface.

A skilled operator taps a few keys on the control screen. The program loads instantly — coordinates, feed rate, spindle speed, and hole depth. Every detail is already calculated to the micrometer.

Hydraulic clamps descend smoothly, locking the square tube in place.

The spindle spins up.

And the drilling begins.

The carbide drill bit touches down, cutting into the stainless steel with a clean, steady sound. A thin stream of coolant flows over the point, cooling and clearing chips as the bit advances. In seconds, the first hole appears — clean-edged, burr-free, and perfectly round.

The Rhythm of Automation

The CNC drilling machine moves with elegant precision.

Drill. Retract. Shift. Drill again.

Hole after hole, perfectly spaced down the tube's length.

The machine doesn't pause, doesn't hesitate. Its multi-axis servo system ensures every movement aligns with the programmed coordinates — not a millimeter off.

From a distance, the scene feels almost hypnotic: the steady hum of the spindle, the smooth motion of the drill head, and the soft hiss of coolant in rhythm with each cut.

This is automation at its best — the blend of mechanical power and digital intelligence.

Why Stainless Steel Drilling Matters

Stainless steel is beautiful, durable, and resistant to corrosion — but it's also tough to machine. The metal's hardness and tendency to work-harden under friction make manual drilling slow and inconsistent.

That's where automation changes everything.

With a fully automatic stainless steel drilling machine, every parameter — speed, torque, pressure, and depth — is controlled electronically. The result: consistent, high-precision holes with minimal tool wear.

Whether for architectural frames, furniture structures, or industrial piping, stainless steel square tubes need to meet exacting standards. Each hole must align perfectly for screws, bolts, or assembly fixtures. There's no margin for error — and no better tool than a CNC-controlled drilling system to get it right every time.

Efficiency Without Human Error

In the past, drilling multiple holes along a tube was a tedious task — measuring, marking, aligning, repositioning. Now, automation makes it effortless.

Once the operator uploads the digital drawing, the CNC machine handles everything.

It aligns, drills, and even clears chips automatically.

Some advanced systems — like those developed by DUOMI CNC — include multi-spindle heads that can drill several holes simultaneously. That means less time, less labor, and higher productivity.

A single operator can now manage multiple machines, focusing on quality control rather than manual labor. It's a quiet revolution happening in workshops around the world.

The Technology Inside

Behind the smooth exterior of the machine lies advanced technology engineered for precision:

CNC Control System – Coordinates every motion with sub-millimeter accuracy.

High-Speed Spindle – Optimized for stainless steel drilling, reducing friction and heat.

Servo Motors & Ball Screws – Deliver fast, stable motion for exact positioning.

Coolant Circulation System – Keeps the cutting zone clean and cool.

Automatic Chip Removal – Prevents blockages and improves cutting efficiency.

Together, these components allow multi-hole CNC drilling to reach levels of speed and accuracy that manual machines simply can't match.

Real-World Applications

The demand for precision-drilled stainless steel tubes spans multiple industries.

Architecture: Railing systems, facades, and structural frames.

Furniture Manufacturing: Lightweight but durable stainless components.

Automotive and Aerospace: Structural frames and mounting systems.

Marine Engineering: Corrosion-resistant tubing for harsh environments.

Industrial Equipment: Precision holes for fluid and air systems.

In all these sectors, fully automatic CNC drilling machines like those from DUOMI CNC ensure uniform hole placement, clean finishes, and superior product consistency.

Smart Manufacturing in Action

This kind of automation doesn't just save labor — it builds smarter factories.

Modern CNC drilling systems can connect to production networks, track performance, and adjust settings automatically. Operators can monitor drill bit wear, predict maintenance needs, and even collect performance data remotely.

That's Industry 4.0 in motion — where every machine learns, adapts, and performs more efficiently over time.

And the result?

More uptime, fewer errors, and higher quality.

The Human Side of Automation

There's still a human touch to all this technology. The operator monitors the process, checks the first few pieces for precision, and fine-tunes the program if needed.

When the drill head lifts after the final pass, the stainless steel tube emerges covered with perfect, gleaming holes. The operator inspects them — smooth edges, no burrs, exactly 6mm in diameter.

Satisfied, they place it on the finished stack, ready for the next stage of production.

Automation doesn't replace craftsmanship; it amplifies it. It gives skilled machinists the power to do more, faster, and with higher accuracy than ever before.

A Quiet Revolution in Metalworking

Every day, in workshops like this, the sound of progress is a steady hum — not the chaos of sparks and hammering, but the calm precision of automated drilling.

Each drilled tube is a testament to the power of technology and the pursuit of perfection.

With fully automatic CNC drilling, what used to take hours now takes minutes. The quality is repeatable, the process traceable, and the results — flawless.

Machines like those built by DUOMI CNC are redefining what's possible in metal fabrication. From micro-holes as small as 0.03mm to large industrial bores, they deliver consistent precision across all materials — steel, aluminum, brass, and more.

Conclusion

So, when you see a stainless steel handrail, a polished structure, or a piece of industrial tubing with perfectly aligned holes — remember, those holes weren't made by hand.

They were created by machines designed with intelligence, accuracy, and purpose.

The Fully Automatic Multi-Hole Drilling Machine represents not just technological progress, but the evolution of human craftsmanship — from manual skill to digital mastery.

And that's what makes it so remarkable.

CNC drilling machine, stainless steel tube drilling, multi-hole CNC drilling, automatic drilling system, CNC drilling and tapping machine, DUOMI CNC, stainless steel fabrication, precision drilling, automated metal drilling, stainless steel square tube machine.