The Evolution of Metal Drilling and Tapping

In the fast-paced manufacturing world, every second matters. Traditional drilling methods—especially when working with stainless steel or aluminum—often face challenges such as tool wear, low precision, and time-consuming setup. Enter thermal friction drilling and CNC tapping technology, an advanced process that eliminates welding nuts, improves thread strength, and enhances overall productivity.

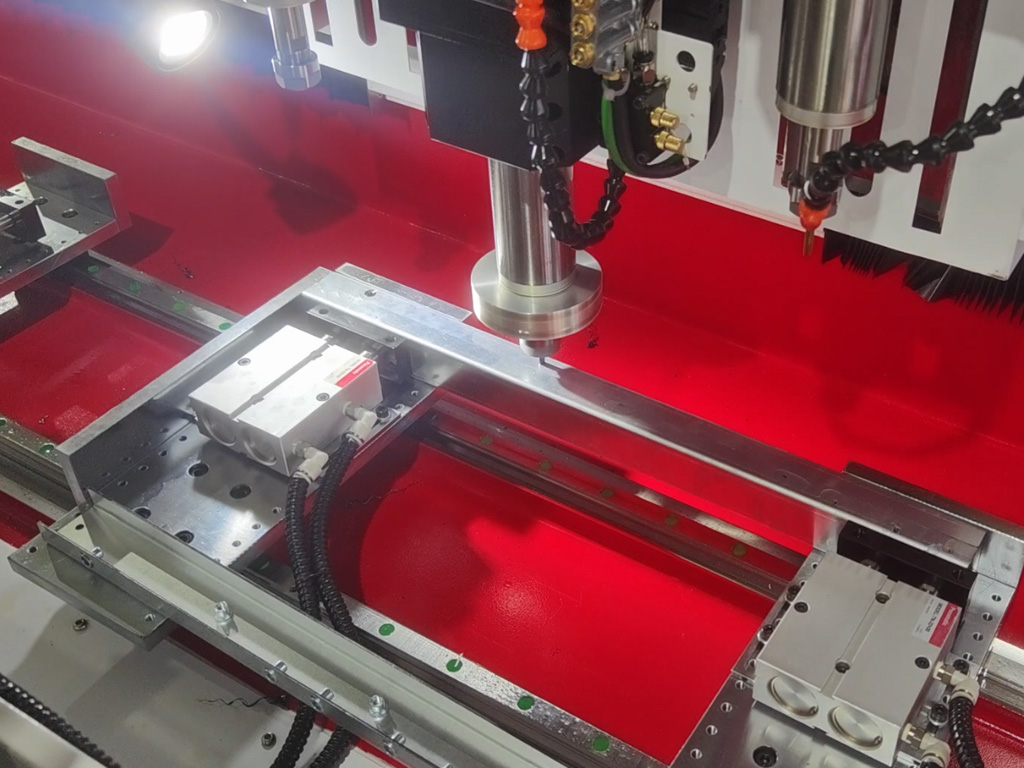

DUOMI CNC, one of the most trusted manufacturers in China, is leading this transformation with its high-performance CNC drilling and tapping machines designed for demanding industrial environments. From automotive components to gym equipment frames, DUOMI's machines are engineered to redefine what precision means in metal fabrication.

What Is Thermal Friction Drilling?

Thermal friction drilling is a solid-state process that uses heat and friction generated by a rotating tool to form holes in metal rather than cutting them.

The friction softens the metal, allowing the tool to displace material and form a bushing with extended wall thickness—perfect for threading without additional nuts or inserts.

Key Advantages:

No material waste

Stronger internal threads

Reduced welding or fastening steps

Clean and burr-free holes

Ideal for thin-walled metals like steel, brass, copper, and aluminum

Why Combine It with a CNC Tapping Machine?

The combination of thermal drilling and CNC tapping brings automation and accuracy to a new level. Instead of manually tapping holes, the CNC control system coordinates tool rotation, feed rate, and torque for consistent thread quality.

Precision Through Automation

Each CNC tapping machine by DUOMI CNC integrates servo motors and digital feedback systems, ensuring each hole and thread are consistent across thousands of parts—critical for industries requiring tight tolerances.

Time Efficiency

Compared with manual or semi-automatic tapping, DUOMI's systems cut processing time by up to 60%, enabling large-scale production without quality loss.

Cost Reduction

By combining drilling, forming, and tapping into one cycle, manufacturers save on labor, tooling, and secondary processes. Less downtime, fewer operators, and no nut welding—all lead to substantial long-term cost savings.

Real-World Customer Success Stories

Automotive Component Supplier (Germany)

A German auto parts manufacturer used DUOMI's 4-axis CNC thermal drilling machine to replace traditional punching and welding processes.

Result: 45% production efficiency increase

Tool life extended by 5×

Consistent hole quality on 2mm stainless-steel frames

Fitness Equipment Factory (Brazil)

A fitness equipment producer struggled with thread strength on tubular steel parts. After switching to DUOMI CNC's thermal friction drilling and tapping solution, they eliminated nut welding entirely.

Output: +30% monthly productivity

Rejected parts: Reduced from 7% to 1%

ROI: Payback within 6 months

HVAC Tube Manufacturer (Thailand)

For copper cooling pipe production, a Thai client adopted DUOMI's multi-spindle CNC tapping machine.

Outcome: Parallel drilling on multiple tubes simultaneously

Efficiency gain: 70% faster cycle times

Precision tolerance: ±0.02mm on threaded holes

Inside DUOMI CNC's Advanced Design

DUOMI CNC machines are built for longevity, precision, and flexibility. Here's what sets them apart:

1. Rigid Machine Structure

The base is made of cast iron to ensure vibration-free operation, critical for high-speed drilling and tapping.

2. Intelligent CNC Control

The user-friendly operation panel (with multilingual interface) supports G-code programming, real-time monitoring, and automatic tool change functions.

3. High-Speed Spindle System

DUOMI CNC machines reach up to 10,000 RPM, maintaining consistent torque output even in heavy-load drilling.

4. Integrated Coolant System

A closed-loop cooling system prevents tool overheating during long production runs—essential for maintaining accuracy in thermal drilling.

Applications Across Industries

DUOMI CNC thermal friction drilling and tapping machines are widely used in:

Furniture and display racks – for strong internal threads in thin tubes

Automotive chassis and frames – lightweight but durable joints

Bicycle and motorcycle frames – precision holes on round or square tubes

HVAC systems and liquid-cooling tubes – seamless drilling for high-pressure resistance

Construction structures – reliable fastening points for metal beams and railings

Each application benefits from reduced welding, higher thread integrity, and optimized cycle time.

Unlike low-cost alternatives, DUOMI CNC integrates precision engineering, after-sales support, and global customization service.

Their R&D center continuously updates control algorithms to support advanced materials like titanium and high-strength alloys.

Global Reach

DUOMI CNC machines are exported to over 40 countries, including the USA, Germany, Mexico, and Vietnam, with local service partners ensuring fast support.

Customer-Centric Philosophy

Each project starts with a free feasibility test, where DUOMI engineers analyze your material type, hole diameter, and production volume to recommend the most efficient solution.

How to Choose the Right CNC Drilling and Tapping Machine

When selecting a machine, consider:

Material type (stainless steel, aluminum, etc.)

Hole size and thread pitch requirements

Production volume (small batch vs. continuous line)

Automation level (manual, semi-auto, or full CNC)

Support and warranty – DUOMI CNC provides 24/7 technical consultation

Future of CNC Drilling and Tapping Technology

With increasing automation demand, the next generation of CNC tapping machines will integrate:

AI-driven tool monitoring

Predictive maintenance

Real-time IoT connectivity

Energy-efficient servo drives

DUOMI CNC is already investing in AI-enhanced control platforms to ensure clients stay ahead of global manufacturing trends.

Conclusion: Redefining Efficiency with DUOMI CNC

The shift toward thermal friction drilling and CNC tapping is not just a manufacturing upgrade—it's a transformation. Companies adopting this technology report dramatic improvements in durability, cost efficiency, and output speed.

As industries push for lighter, stronger, and more sustainable designs, DUOMI CNC remains a global leader in helping manufacturers transition to next-generation drilling and tapping solutions.

Call to Action (CTA):

Ready to enhance your production efficiency?

Contact DUOMI CNC today for a free consultation and customized machine recommendation.