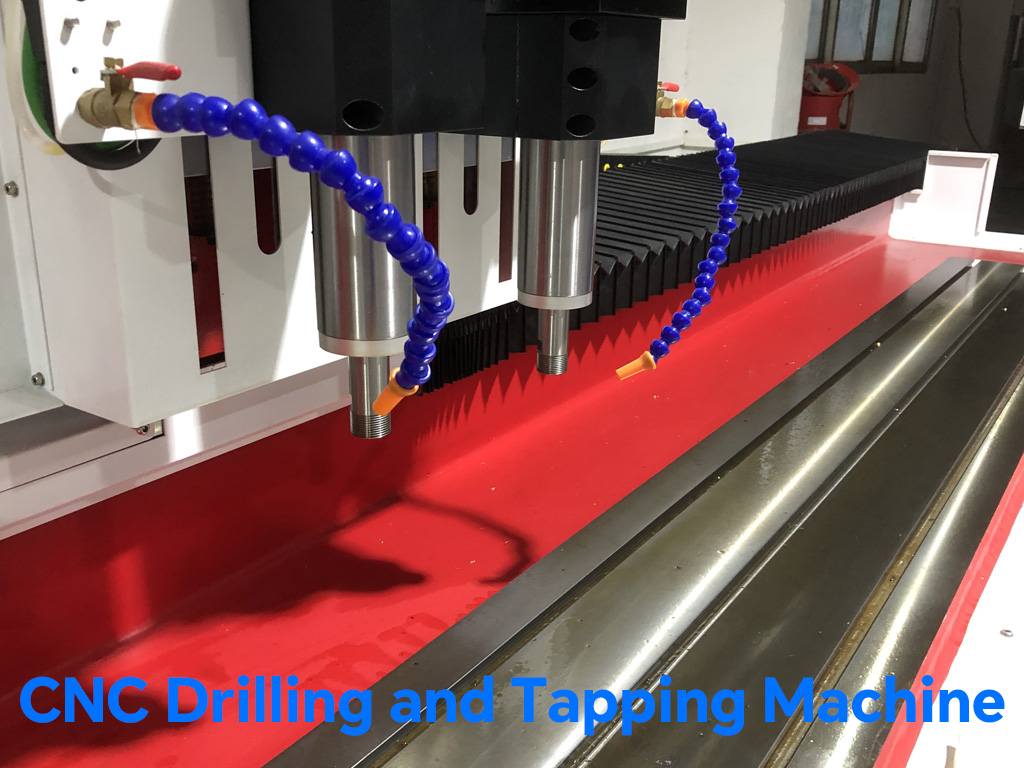

A CNC Drilling and Tapping Machine is an advanced automated machine tool that integrates both drilling and tapping functions under precise CNC (Computer Numerical Control) programming. It is specifically designed for high-speed, high-accuracy machining of holes and threads in metal or non-metal components.

Key Features of a CNC Drilling and Tapping Machine:

CNC Automation: The machine operates through pre-programmed instructions, ensuring consistent and precise hole positioning and thread cutting.

Integrated Drilling & Tapping: One setup completes both operations without manual repositioning, saving time and reducing errors.

Material Versatility: Works with materials such as mild steel, stainless steel, aluminum, brass, copper, and more.

High Production Efficiency: Ideal for mass production and continuous operation with minimal human intervention.

Precision Engineering: Built with servo motors, ball screws, and linear guideways to ensure micron-level accuracy.

Multi-Spindle Options: Available in single-spindle and multi-spindle models to meet different volume needs.

Common Applications:

Furniture Manufacturing: For drilling and tapping square tubes used in table and chair frames.

Fitness Equipment: Machining of steel tubes in exercise machines.

Automotive Parts: Precise drilling/tapping of brackets, mounting plates, and components.

Display Racks & Shelving: High-volume hole processing in metal profiles.

Metal Hardware: For precise thread-making in small metal parts and fixtures.

Compared to Traditional Machining:

| Feature | CNC Drilling & Tapping Machine | Traditional Manual Setup |

|---|---|---|

| Operation | Fully automatic (CNC) | Manual or semi-automatic |

| Accuracy | High precision | Depends on operator skill |

| Setup Time | One-time setup | Multiple setups required |

| Labor Requirement | Minimal | High |

| Productivity | High-speed continuous | Slower, less efficient |

| Cost Over Time | Cost-effective in long run | Higher due to labor & time |

Why Choose a CNC Drilling and Tapping Machine?

If you're in a metalworking industry looking to boost production, improve accuracy, and reduce labor costs, a CNC drilling and tapping machine is a smart investment. It significantly enhances manufacturing efficiency and consistency, especially for batch processing of square tubes, plates, or custom components.

Need Help Choosing the Right Model?

If you're producing items like fitness frames, furniture metal parts, or automotive brackets, we can help you select the ideal CNC drilling and tapping machine to match your material, hole size, and thread requirements.