If you're still relying on outdated manual or semi-automatic drilling and tapping methods in your shop, it's time to rethink your production game. The modern Drilling and Tapping Center—like the high-performance systems from DUOMI CNC—is built to do one thing extremely well: help you save time, reduce labor costs, and increase precision. In this article, we'll break down how a CNC drilling and tapping center changes the game for manufacturers in the U.S. and globally.

What is a Drilling and Tapping Center?

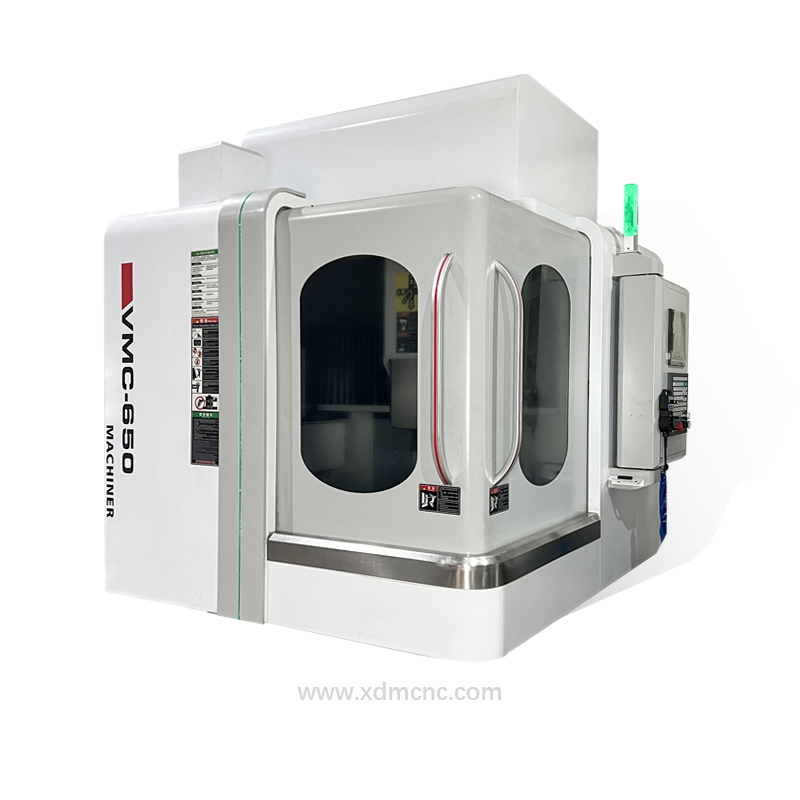

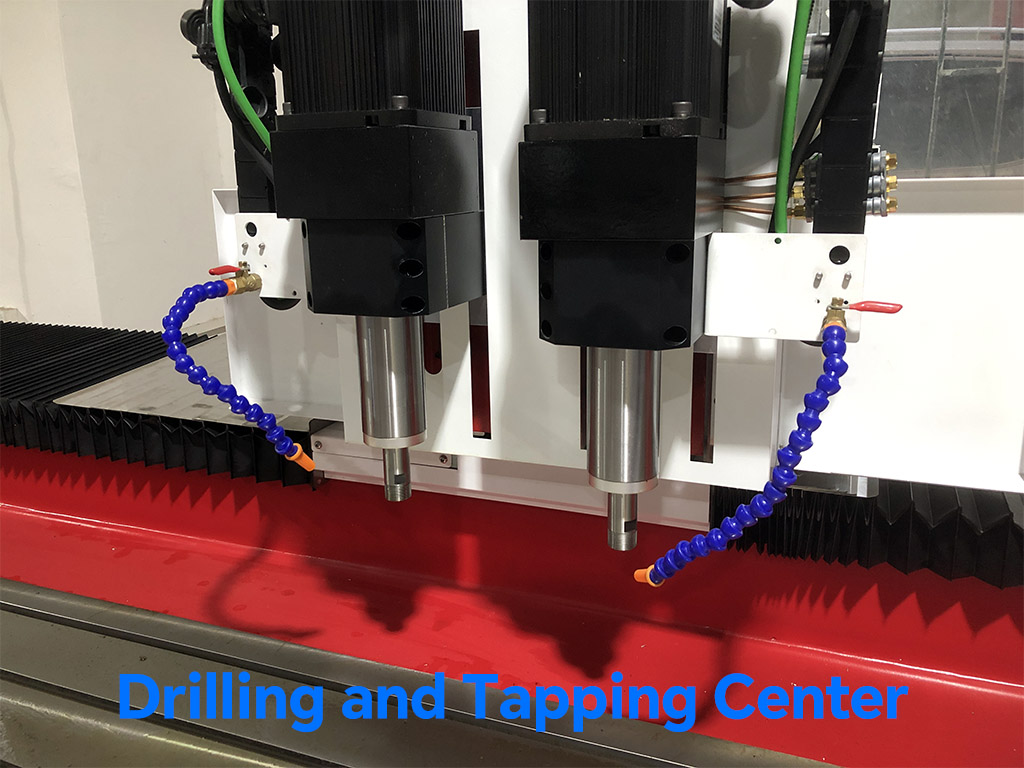

A drilling and tapping center is a compact, high-speed CNC machine designed to perform both drilling and tapping operations with incredible accuracy. These machines are equipped with automatic tool changers, rigid tapping functions, and high-speed spindles—perfect for production lines that demand efficiency and repeatability.

DUOMI CNC offers U.S.-grade quality machines that are optimized for processing aluminum, steel, copper, and stainless materials commonly used in auto parts, furniture frames, electronics, and more.

Why Traditional Methods Are Holding You Back

Let's face it—manual drilling and tapping are time-consuming, labor-intensive, and error-prone. Here's how traditional methods are hurting your bottom line:

1. Inconsistent Accuracy

Every operator works a little differently. Manual methods introduce variations in hole depth, position, and thread quality. A drilling and tapping center eliminates human error by automating every step.

2. High Labor Costs

Traditional setups often require skilled technicians to operate, measure, and correct the work. With a CNC drilling and tapping center, a single operator can manage multiple machines with little training.

3. Slow Throughput

Manual processes are significantly slower. In today's competitive market, speed equals money. DUOMI CNC machines cut cycle times dramatically, allowing you to take on more orders and meet tight deadlines.

4. Tool Life Waste

Conventional systems don't optimize spindle speeds or feed rates, leading to rapid tool wear. Our CNC systems use intelligent control to extend tool life and cut down replacement costs.

Boost Efficiency with a DUOMI CNC Drilling and Tapping Center

When you invest in a DUOMI CNC drilling and tapping center, you're not just buying a machine—you're upgrading your entire workflow. Here's how:

High-Speed, High-Precision

Equipped with servo motors, precision guides, and rigid tapping capability, DUOMI CNC machines maintain exact tolerances, even under continuous use. This means fewer reworks and higher customer satisfaction.

One Machine, Two Operations

Instead of moving your parts from a drill press to a tapping machine, the DUOMI drilling and tapping center completes both operations in one cycle. This saves floor space and reduces handling time.

Automated Everything

With automatic tool changers, digital control interfaces, and optional loading arms, the system reduces reliance on human input. Automation minimizes downtime and boosts consistency.

Real ROI—Not Just Hype

We get it: upgrading equipment isn't cheap. But when you factor in labor savings, reduced scrap, improved turnaround times, and the ability to win more contracts, the numbers speak for themselves.

Many of our clients report seeing ROI in as little as 2 to 6 months after switching to a DUOMI CNC drilling and tapping center.

Industries That Rely on DUOMI CNC

Our machines are trusted across a range of industries:

Automotive parts (engine brackets, brake housings)

Fitness equipment (steel tubes, frame joints)

Furniture manufacturing (metal frames, support rails)

Electrical cabinets (aluminum plates, copper bars)

If your process involves metal parts with multiple threaded holes, a DUOMI CNC drilling and tapping center is your next best move.

Final Thoughts—Step Into Smart Manufacturing

There's never been a better time to leave old-school methods behind. A drilling and tapping center from DUOMI CNC delivers the speed, reliability, and accuracy modern manufacturers need to stay ahead.

Ready to scale your productivity and reduce operational headaches? Let DUOMI CNC help you make the shift today.