Unlock Precision and Efficiency with Advanced Small Hole Drilling Machines

In the world of modern manufacturing, small hole drilling is no longer a niche requirement—it's a critical process in industries where precision, speed, and repeatability are non-negotiable. Whether you're producing aerospace components, medical devices, electronics, or high-end automotive parts, the need for accurate and consistent small diameter holes is growing rapidly.

What is Small Hole Drilling?

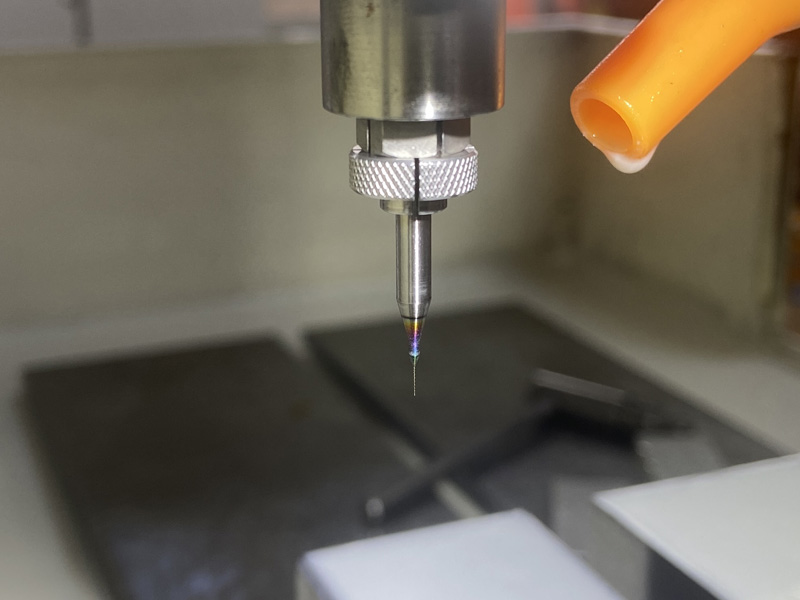

Small hole drilling refers to the process of creating holes typically ranging from 0.03mm to 2mm in diameter. Unlike conventional drilling, this technique requires specialized machinery, high-speed spindles, and precise tool alignment to ensure hole accuracy, depth control, and surface finish.

Small holes are often required in:

Printed Circuit Boards (PCBs)

Fuel injection nozzles

Cooling channels for molds

Medical implants and surgical tools

Microelectronics and sensor components

Why Choose a Small Hole Drilling Machine?

Traditional drilling machines struggle with micro-sized holes due to issues like tool deflection, heat build-up, and surface quality. That’s why dedicated small hole drilling machines have become essential for manufacturers demanding exact tolerances and high-throughput production.

Key Features of a High-Quality Small Hole Drilling Machine:

High-Speed Spindle (Up to 60,000 RPM or more)

Enables clean and fast micro-hole drilling without compromising precision.

Precision Servo Control

Ensures repeatable positioning and accurate hole placement.

CNC Programming Capability

Allows complex drilling patterns, automated operation, and minimal manual error.

Stable Frame and Vibration Dampening

Critical for reducing tool wear and ensuring surface finish quality.

Advanced Cooling and Chip Removal Systems

Keeps the drilling environment clean and prevents thermal deformation.

Benefits of Small Hole Drilling Technology

✅ Superior Accuracy

Achieve tolerances as tight as ±0.01mm, perfect for high-spec applications.

✅ Increased Productivity

Multi-axis CNC systems can handle complex jobs with minimal downtime.

✅ Material Versatility

Suitable for drilling in stainless steel, titanium alloys, copper, plastics, and ceramics.

✅ Longer Tool Life

Optimized speeds and cooling help reduce tool wear, cutting operational costs.

Applications Across Key Industries

Small hole drilling machines are now indispensable in:

Aerospace & Defense: Cooling holes in turbine blades, precision fastener holes.

Electronics: Via holes in multilayer PCBs.

Medical: Micro-holes in orthopedic implants and surgical instruments.

Automotive: Fuel system components and engine cooling channels.

Mold & Die Making: Micro-channel and ejector pin holes.

Why Choose Our Small Hole Drilling Solutions?

We offer a range of small hole CNC drilling machines tailored to meet diverse manufacturing needs. Our machines are engineered for maximum precision, low maintenance, and user-friendly operation—helping you stay ahead of the competition.

From custom-built micro-drilling setups to ready-to-ship standard models, our solutions are backed by expert service, global support, and proven performance in demanding production environments.

Looking for the best small hole drilling machine for your workshop?

Let us help you transform your production capabilities. Contact us today for a free consultation or request a quote!

Keywords: small hole drilling, CNC micro drilling machine, precision drilling, high-speed spindle drilling, medical device drilling, aerospace drilling solution, micro hole CNC, micro drilling equipment