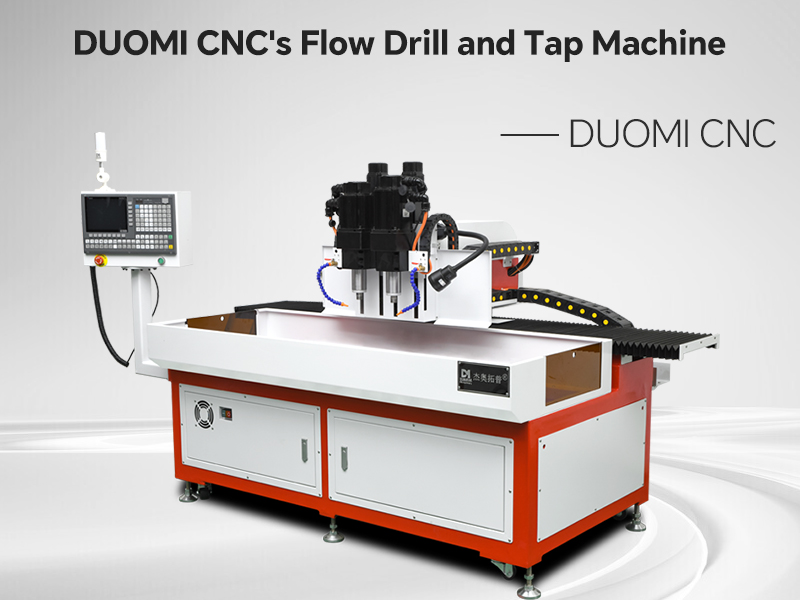

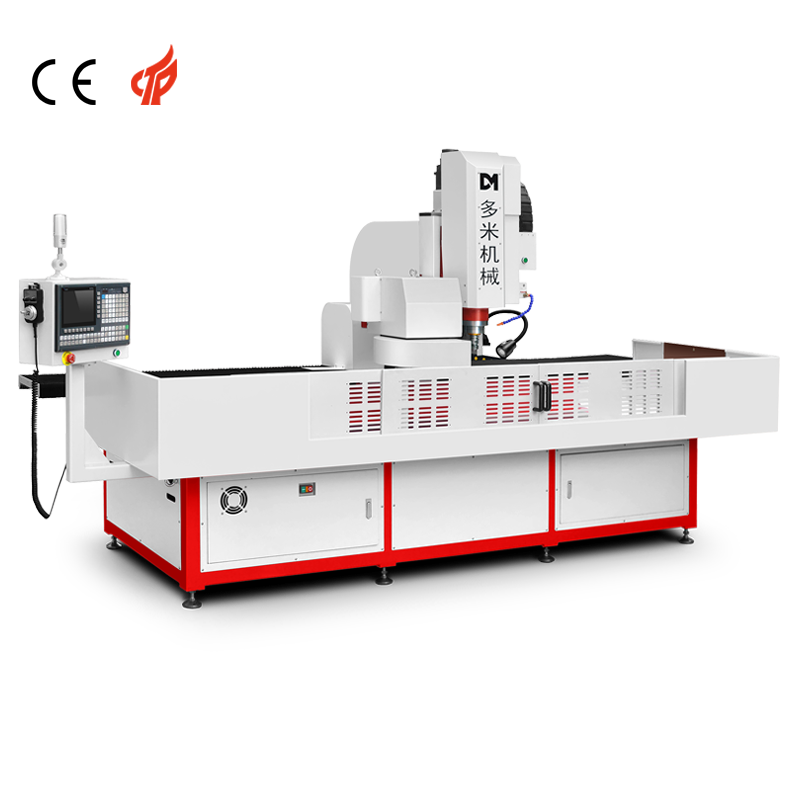

Want to see how DUOMI CNC's Flow Drill Machine performs on your parts? We offer free drilling and tapping tests on your samples—complete with video, parameters, and hole strength analysis.

✅ Stronger, Safer Threaded Connections

The flow-drilled holes create a longer thread engagement, resulting in vibration-resistant, structurally stronger joints, critical for automotive safety and long-term reliability.

✅ One-Step Hole + Thread Forming

Drill and tap in a single setup. Greatly reduces cycle time and eliminates extra fixtures, welds, and hardware.

✅ Ideal for Tubes, Sheets & Castings

Works perfectly on mild steel, stainless steel, aluminum, and alloy parts used in the car body, underbody, and powertrain systems.

✅ Global Manufacturing Standard

DUOMI CNC's Flow Drill Machine is trusted by OEM suppliers and automotive factories across Germany, Mexico, Korea, Turkey, and Southeast Asia.

✅ Compact, Intelligent & Scalable

Smart CNC control, auto feeding system, optional multi-spindle setup, and robot integration make it perfect for high-volume production lines.

Click the image for more details

Applications in Automotive Parts:

EV battery trays and modules

Crossmembers and seat supports

Air conditioning brackets

Exhaust mounts

Suspension brackets

Door frame reinforcements