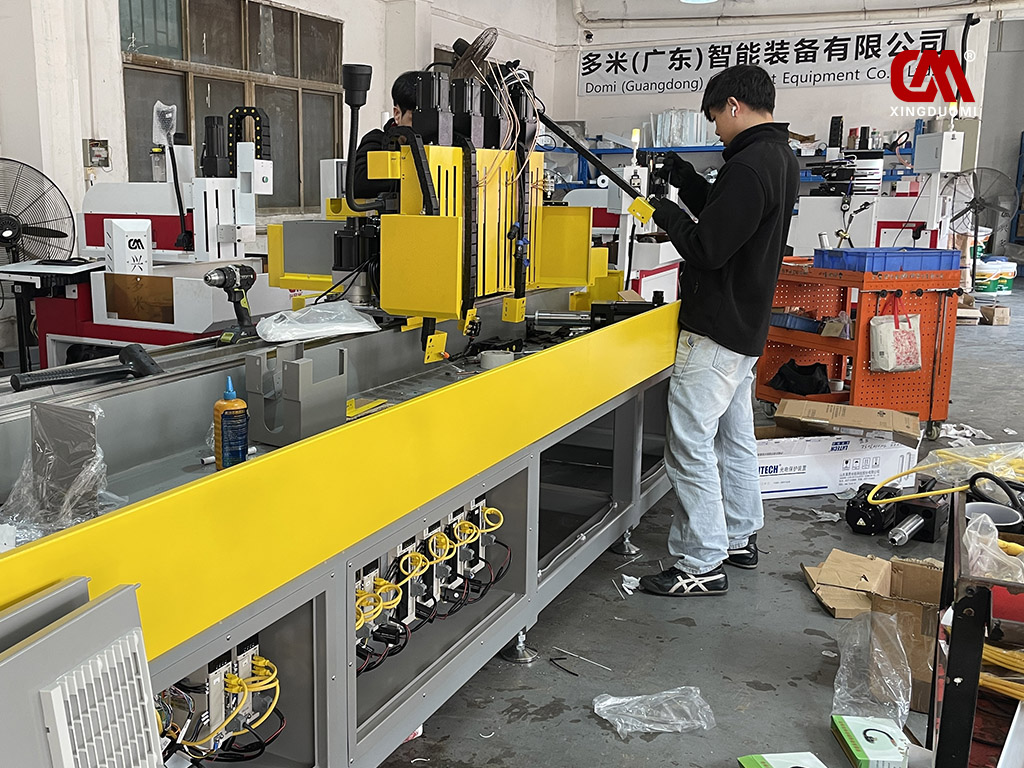

The DUOMI CNC four-spindle thermal drilling and tapping machine is currently under customized manufacturing at the DUOMI factory. This stage focuses on machine structure assembly, system integration, and process-oriented configuration based on specific application requirements.

DUOMI CNC is currently manufacturing a four-spindle thermal drilling and tapping machine

Customized Design and Engineering Preparation

Before assembly, the engineering team reviewed the customer's machining requirements, including material type, hole specifications, and production expectations. Based on these parameters, the four-spindle configuration was confirmed to support synchronized thermal drilling and tapping operations.

Mechanical layout, spindle spacing, and tool arrangement were adjusted during the design phase to ensure proper coordination between drilling and tapping processes within a single machining cycle.

Assembly and Component Integration

The machine is being assembled on the factory floor following standard manufacturing procedures. Key components, including the spindle units, transmission elements, and structural parts, are installed step by step to ensure mechanical alignment and rigidity.

DUOMI CNC machine tool production workshop

Each spindle is mounted and calibrated individually before being integrated into the multi-spindle system. This approach helps maintain consistency across all four units during later synchronous operation.

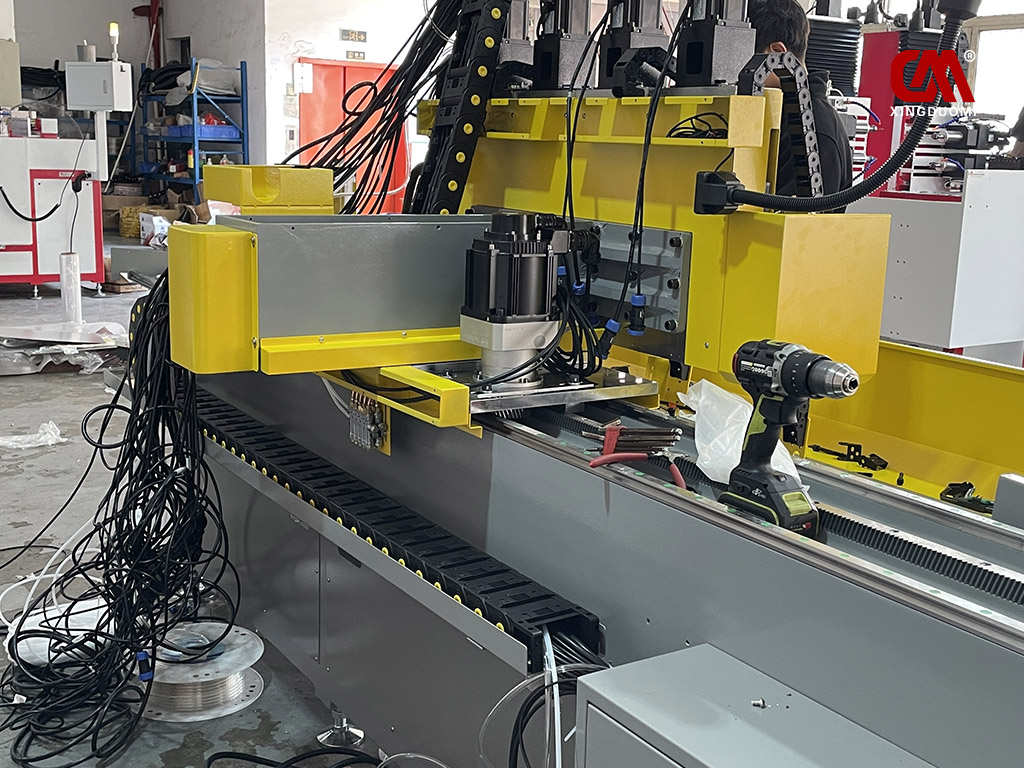

CNC System Configuration and Parameter Setup

During the manufacturing process, the CNC control system is configured according to the customized machining logic. Axis movement, spindle coordination, and drilling–tapping sequences are programmed and verified.

DUOMI CNC engineers are assembling components of the four-spindle thermal drilling and tapping machine

Thermal drilling parameters, tapping depth, and synchronization timing are adjusted at this stage to match the intended application, ensuring that the machine is prepared for stable operation after delivery.

In-Factory Testing and Verification

As part of the manufacturing process, preliminary testing is carried out within the factory. This includes dry runs, axis movement checks, and spindle synchronization tests to confirm proper mechanical response and control logic.

These in-factory verifications allow potential issues to be identified and corrected early, reducing commissioning time after installation at the customer site.

DUOMI CNC engineers are installing the electrical wiring and control components on the thermal drilling and tapping machine

Manufacturing Status

The machine remains in the customized manufacturing phase, with assembly and system integration progressing according to plan. Further functional testing and accuracy verification will be completed before final inspection and shipment.

This manufacturing log reflects DUOMI CNC's approach to application-oriented machine development, emphasizing engineering preparation, controlled assembly, and process verification at the source factory.