The Gas Stove Burner Cap Drilling Machine has revolutionized the manufacturing of gas stove components, playing a vital role in the production of burner caps. These machines provide advanced precision, speed, and consistency, ensuring high-quality products that meet the evolving demands of various global markets. This article will delve into the significance of these machines, highlighting their technical advantages and examining the usage habits and preferences of different countries around the world.

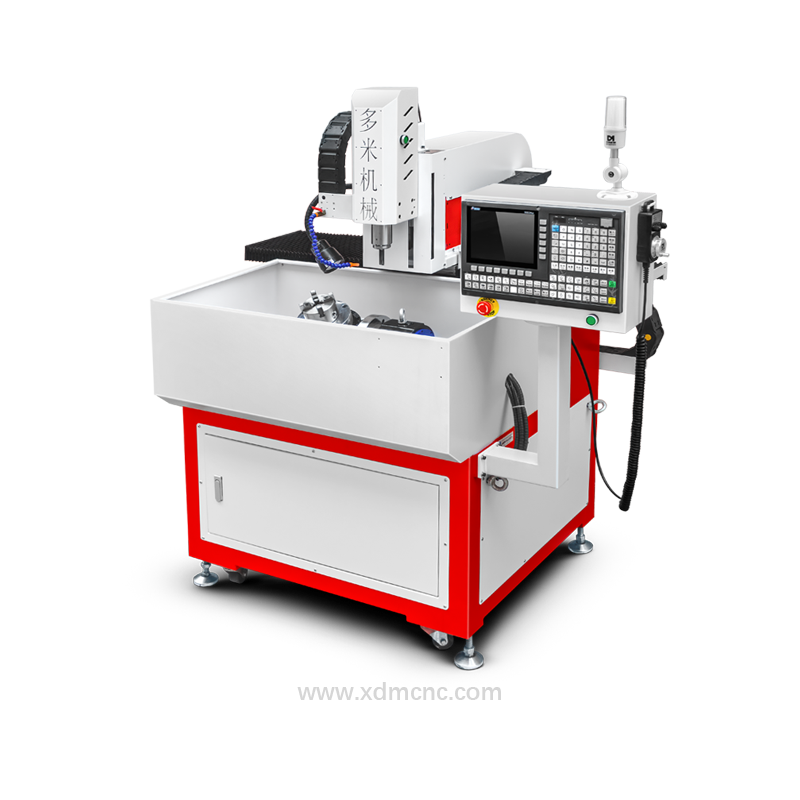

Understanding the Gas Stove Burner Cap Drilling Machine

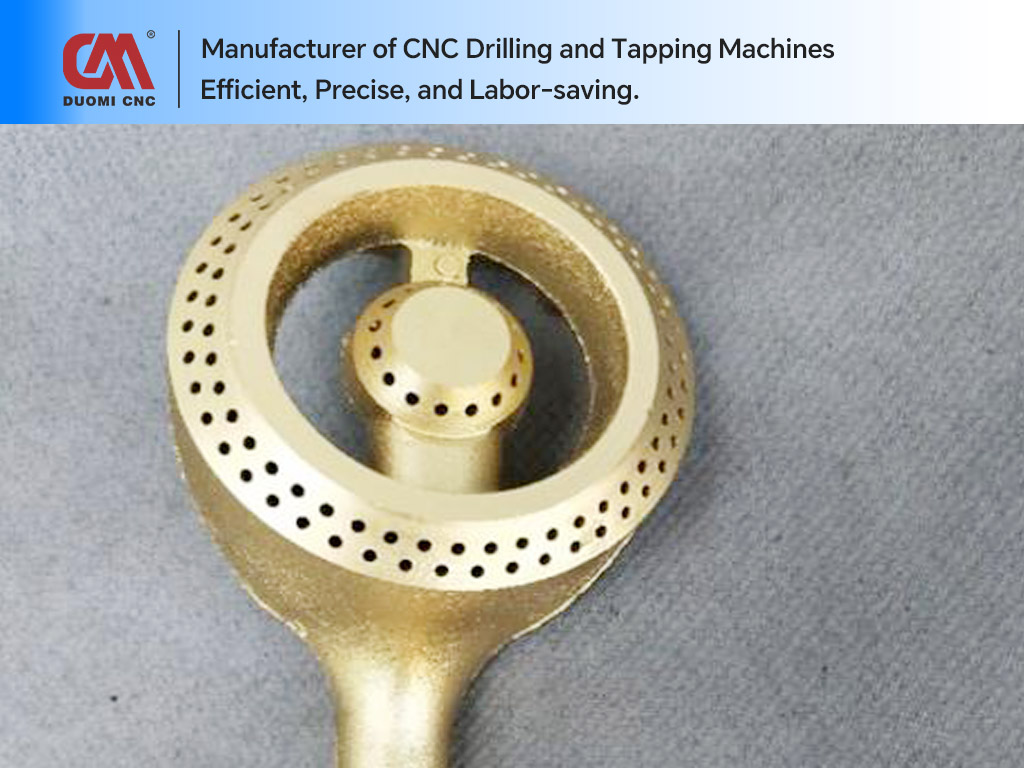

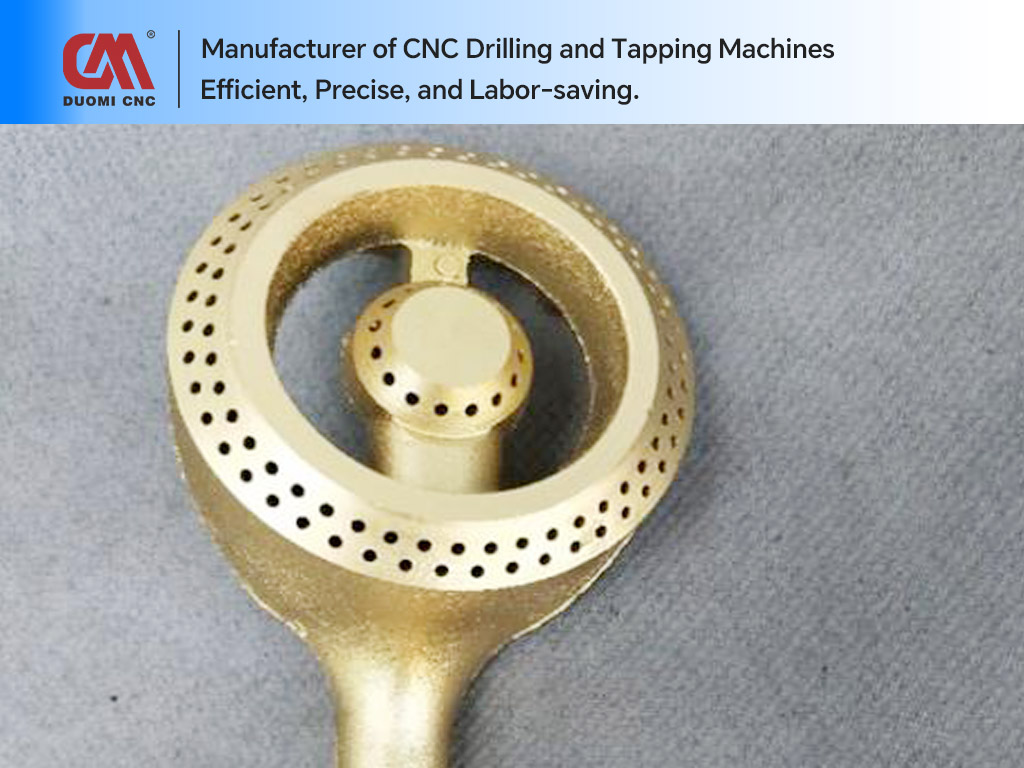

A Gas Stove Burner Cap Drilling Machine is an advanced tool designed to drill holes into burner caps, which are crucial components of gas stoves. Burner caps are responsible for directing the gas flow and controlling the flame distribution. The drilling process involves creating multiple small holes in precise patterns to allow for efficient combustion and optimal flame performance.

The primary functions of the drilling machine include:

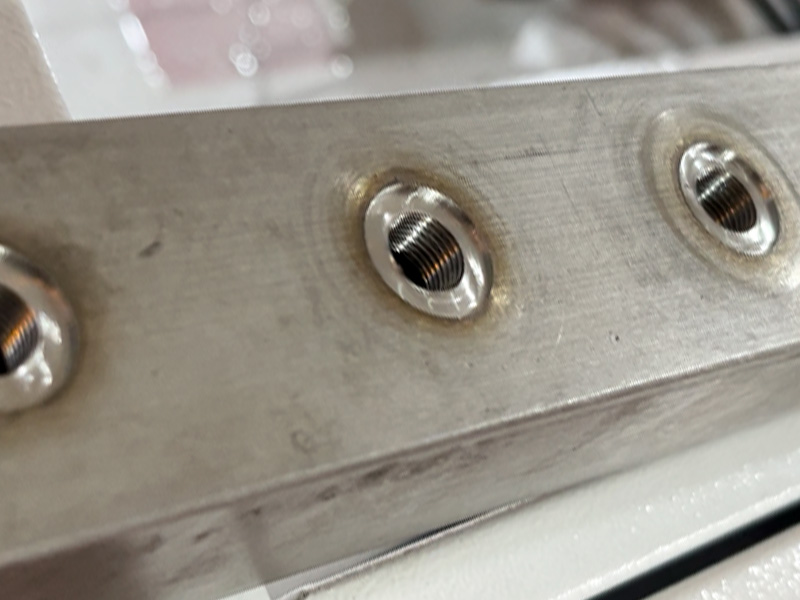

Precision Drilling: Ensures the accuracy of hole size, depth, and alignment.

Multiple Hole Configurations: Capable of drilling several holes in various patterns.

Automated Operation: Reduces human error and increases production speed.

This technology has streamlined the production process, reducing labor costs, enhancing product consistency, and improving overall manufacturing efficiency.

The Global Usage Habits of Gas Stove Burner Cap Drilling Machines

While the Gas Stove Burner Cap Drilling Machine has become a standard tool in many industrial settings, the use and preferences for these machines can vary depending on regional market demands, local manufacturing practices, and consumer expectations. Let’s explore how these machines are used in different countries and regions:

1. United States: Focus on Efficiency and Customization

In the United States, manufacturers of gas stoves prioritize both efficiency and customization. The gas stove market is highly competitive, and consumers demand both quality and variety in their kitchen appliances. The Gas Stove Burner Cap Drilling Machine is commonly used for:

Mass Production: CNC (Computer Numerical Control) drilling machines are widely adopted for high-volume production, offering precise and consistent drilling that aligns with industry standards.

Customization: American manufacturers often use CNC drilling machines to produce burner caps with customized hole patterns and configurations to meet specific consumer needs, such as varying flame intensity and distribution for different cooking styles (e.g., rapid boil or low simmer).

With an increasing demand for energy-efficient appliances, the drilling machine’s precision ensures that the flame distribution is optimal, improving cooking efficiency and reducing gas consumption.

2. China: High-Volume Production and Cost Efficiency

China, as a global leader in manufacturing, has embraced the use of Gas Stove Burner Cap Drilling Machines to maintain its position in the competitive appliance market. The focus in China is on producing high-quality burner caps at a lower cost, catering to both domestic and international markets. Key characteristics of gas stove manufacturing in China include:

Large-Scale Production: The use of CNC drilling machines enables manufacturers to produce burner caps in large quantities with minimal manual labor, reducing production costs significantly.

Affordability: Chinese manufacturers are known for their ability to offer high-quality products at lower prices. CNC drilling machines help achieve this by minimizing material waste and improving operational efficiency.

China’s domestic market has a strong demand for affordable, reliable gas stoves, and CNC drilling technology has played a key role in fulfilling this need while maintaining product quality.

3. Germany: Precision and Quality Control

Germany is renowned for its engineering expertise, and this is reflected in its approach to manufacturing gas stove components. The Gas Stove Burner Cap Drilling Machine in Germany is utilized with a strong emphasis on precision, quality control, and energy efficiency. Features of German manufacturing practices include:

High Precision: German manufacturers prioritize precision and durability in their gas stove components. CNC drilling machines are fine-tuned for exact measurements and consistently produce burner caps that meet stringent quality standards.

Innovation in Design: Germany’s focus on innovation drives the demand for custom burner cap designs. The CNC drilling machine facilitates the creation of unique hole patterns that optimize gas flow and combustion, meeting the needs of premium brands and eco-conscious consumers.

German consumers expect high-end, reliable products, and the drilling machine's precision contributes to the creation of high-quality burner caps that meet these expectations.

4. India: Growing Market with Focus on Durability

India’s growing economy has led to an increased demand for durable and energy-efficient kitchen appliances, including gas stoves. The use of the Gas Stove Burner Cap Drilling Machine in India is expanding, with manufacturers focusing on:

Durability: In a market that values long-lasting products, the drilling machine’s ability to create precise holes ensures that the burner caps are both functional and durable, contributing to the longevity of the gas stoves.

Affordable Production: With cost sensitivity being a key factor for Indian consumers, CNC drilling machines offer a way to produce high-quality burner caps while keeping manufacturing costs low.

As the Indian market continues to grow, the demand for reliable, energy-efficient, and affordable gas stoves drives the increased adoption of CNC drilling technology.

5. Middle East: High Demand for Premium Gas Stoves

In the Middle East, consumers tend to favor high-end appliances that combine aesthetics, functionality, and efficiency. Gas stove manufacturers in this region often rely on Gas Stove Burner Cap Drilling Machines for:

Aesthetic Design: The ability to produce burner caps with unique hole patterns is highly valued in the Middle Eastern market, where kitchen appliances are often seen as a statement of luxury and style.

Efficiency: Consumers in the region also look for gas stoves that offer high efficiency in terms of cooking performance and energy consumption. Precision drilling ensures that the gas flow is optimized for the best cooking results.

The Gas Stove Burner Cap Drilling Machine plays a crucial role in meeting the demands of this discerning market by offering both design flexibility and functional precision.

Conclusion

The Gas Stove Burner Cap Drilling Machine is an essential tool that has transformed the manufacturing of gas stove components globally. From high-volume production in China to precision engineering in Germany, and customization in the United States, these machines have been adopted worldwide to meet the varying needs of different markets. With their ability to improve efficiency, reduce production costs, and enhance product quality, CNC drilling machines are shaping the future of gas stove manufacturing in every corner of the globe.

As global demand for high-quality, efficient, and cost-effective gas stoves continues to grow, the Gas Stove Burner Cap Drilling Machine will remain a key technology in the industry, driving innovation and meeting consumer expectations across diverse regions.