Revolutionizing Wrought Iron Furniture Manufacturing with DUOMI CNC Thermal Friction Drilling Technology

Wrought iron furniture has long been celebrated for its durability, intricate designs, and timeless aesthetic appeal. However, behind its beauty lies a challenging manufacturing process, especially when it comes to joining metal components efficiently and reliably. Traditional methods such as riveting, welding, and mechanical fastening often lead to complicated, time-consuming steps that impact production efficiency and product quality.

The Pain Points of Traditional Joining Methods

In wrought iron furniture production, assembling components typically involves drilling holes followed by riveting or welding nuts and bolts. These conventional techniques bring several challenges:

Labor-Intensive Processes: Manual riveting and welding require skilled labor and careful handling, leading to higher labor costs and inconsistent quality.

Time Consumption: Multiple steps and machine setups slow down production lines, reducing output and increasing lead times.

Potential Structural Weakness: Welding can cause heat distortion or weaken the metal around the joints, compromising furniture strength and longevity.

Surface Damage and Aesthetics: Riveting and welding may leave marks or require additional finishing, affecting the furniture's final appearance.

As the demand for wrought iron furniture grows, manufacturers seek solutions that boost productivity, ensure structural integrity, and maintain aesthetic standards. This is where DUOMI CNC's thermal friction drilling technology steps in as a game-changer.

DUOMI CNC: The Future of Drilling and Tapping for Wrought Iron Furniture

DUOMI CNC, a leading Chinese manufacturer of CNC drilling machines, specializes in advanced thermal friction drilling and tapping equipment tailored for metal fabrication industries, including wrought iron furniture production.

Thermal friction drilling, also known as hot drilling or heat drilling, uses friction-generated heat to create precise, burr-free holes and threaded connections without removing metal chips. This process offers significant advantages over traditional drilling and fastening techniques.

Advantages of Using DUOMI CNC Thermal Friction Drilling Machines

Elimination of Riveting and Welding Steps

DUOMI CNC thermal friction drilling machines allow manufacturers to drill and tap holes directly into wrought iron components, enabling fast and reliable screw fastening. This eliminates the need for separate riveting or welding nuts, simplifying the assembly process and reducing labor costs dramatically.

Enhanced Production Efficiency

The thermal friction drilling process is highly automated and fast. DUOMI CNC machines can complete drilling and tapping in one cycle, accelerating production speed and increasing throughput. Manufacturers benefit from shorter lead times and faster order fulfillment.

Improved Joint Strength and Durability

Unlike welding, thermal friction drilling generates minimal heat impact on the surrounding metal, preserving the structural integrity of wrought iron pieces. The threaded holes produced are strong and precise, ensuring secure connections that withstand mechanical stress and environmental conditions.

Superior Surface Finish and Aesthetics

DUOMI CNC's thermal drilling technology creates clean, burr-free holes with no deformation or discoloration. This means less need for secondary finishing processes, maintaining the furniture's visual appeal and reducing manufacturing steps.

Cost-Effective and Sustainable Manufacturing

By cutting down on welding and riveting consumables and minimizing scrap metal from chip removal, DUOMI CNC's solution reduces material waste and lowers overall production costs. The streamlined process also reduces energy consumption, supporting more sustainable manufacturing practices.

Industry Applications and Success Stories

Many wrought iron furniture manufacturers globally have adopted DUOMI CNC thermal friction drilling machines to transform their production lines. From garden benches and ornate chairs to decorative tables and gates, the benefits have been evident:

Faster assembly lines leading to increased capacity

Consistent product quality with fewer defects

Lower operational costs and reduced workforce strain

Enhanced product aesthetics that appeal to discerning customers

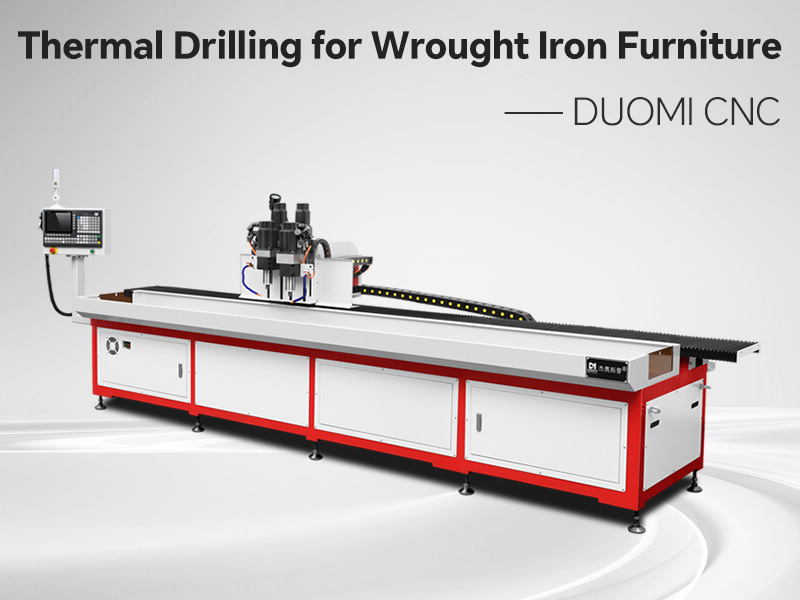

Click on the image for more details

Why Choose DUOMI CNC?

With years of experience and a strong reputation in the CNC machining industry, DUOMI CNC offers not just advanced equipment but also comprehensive global technical support and customized solutions. Their machines are designed for ease of integration into existing production setups and come with training and after-sales services to ensure smooth operation.

Conclusion

For manufacturers aiming to innovate wrought iron furniture production, DUOMI CNC's thermal friction drilling technology offers a powerful solution to longstanding challenges. By eliminating the tedious riveting and welding processes, enhancing efficiency, and delivering superior product quality, DUOMI CNC helps businesses stay competitive and meet growing market demands.

If you're ready to upgrade your manufacturing capabilities and embrace the future of CNC drilling technology, contact DUOMI CNC today and discover how thermal friction drilling can revolutionize your wrought iron furniture production.