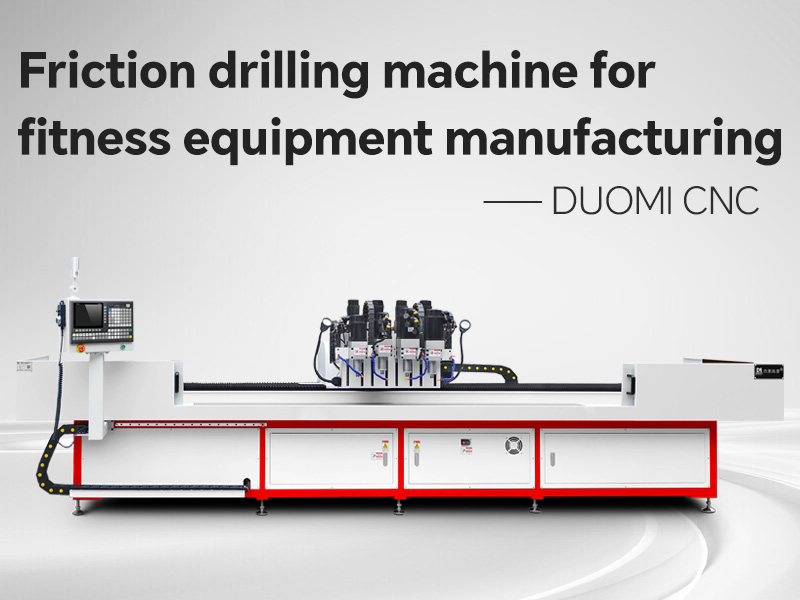

Revolutionizing Fitness Equipment Manufacturing with DUOMI CNC Friction Drilling Machines

In the ever-evolving fitness industry, precision, durability, and efficiency are paramount. Whether it's gym benches, squat racks, or elliptical machine frames, the demand for robust and aesthetically clean joints is on the rise. Enter friction drilling technology—a transformative solution that is reshaping how fitness equipment is made. Among the leading innovators in this field, DUOMI CNC stands out with its high-performance friction drilling machines, purpose-built for modern fitness equipment manufacturing.

What is Friction Drilling?

Friction drilling, also known as thermal friction drilling, is a non-traditional method of hole formation in metal tubes and sheets. Instead of cutting, this process utilizes high-speed rotation and heat to displace material and form a hole with a reinforced bushing. This bushing serves as a strong base for threading or fastening—eliminating the need for welding, inserts, or nuts.

In the context of fitness equipment manufacturing, friction drilling is particularly effective for steel tubes, aluminum profiles, and iron frames, which are commonly used in gym structures and home workout equipment.

Why Choose Friction Drilling for Fitness Equipment?

The benefits of friction drilling are aligned perfectly with the needs of the fitness industry:

Stronger Connections: The bush formed during the drilling process increases the thread engagement, leading to more secure joints that can handle repetitive stress.

No Welding Required: Welding adds time, cost, and risk of corrosion. Friction drilling removes the need for welding in tube-to-tube and tube-to-plate joints.

Clean Aesthetics: Fitness equipment must look professional. Friction drilling leaves clean, burr-free holes that are visually superior to traditional drilling.

High Efficiency: The process is fast and suitable for high-volume production, which helps manufacturers meet growing market demand.

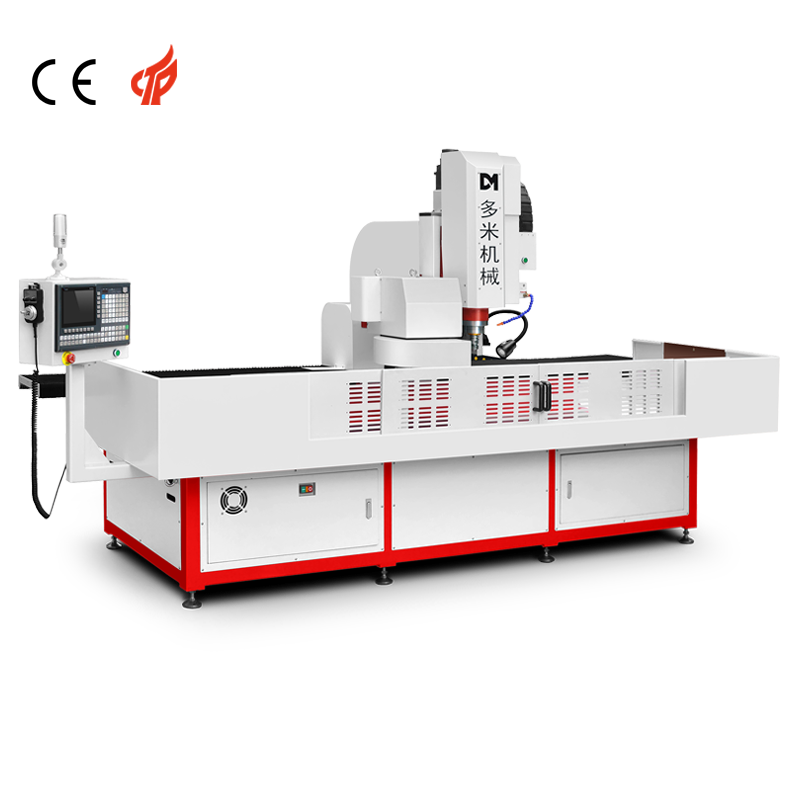

DUOMI CNC: A Trusted Name in Friction Drilling

At the forefront of this technology is DUOMI CNC, a leading Chinese manufacturer specializing in CNC friction drilling and tapping machines. With years of experience and innovation, DUOMI CNC offers a range of intelligent, efficient, and customizable machines designed specifically for industries like fitness, automotive, furniture, and display rack manufacturing.

Key Features of DUOMI CNC Friction Drilling Machines:

Precision Control System: Ensures consistent hole quality with programmable parameters.

Integrated Tapping Function: One machine handles both drilling and tapping, reducing setup time.

Heavy-Duty Build: Engineered to handle thick steel tubes commonly used in gym equipment.

Energy Efficient: Uses less power than traditional welding and drilling processes.

Easy Operation: Touchscreen interface and user-friendly programming make it accessible to all levels of operators.

Case Applications: Fitness Equipment Production

Several global fitness equipment manufacturers have upgraded their production lines with DUOMI CNC machines, reporting improvements in assembly strength, visual quality, and production speed. Whether it's for commercial gym installations or home-use multi-functional machines, DUOMI CNC friction drilling solutions enhance every stage of the production process.

Ideal for:

Power Racks

Squat and Bench Frames

Cable Machines

Leg Press Structures

Dumbbell Racks

Home Gym Kits

Vietnamese fitness equipment manufacturers choose DUOMI CNC friction drilling and tapping machines.

By replacing traditional welding and nut-insert methods with DUOMI CNC friction drilling, companies reduce material costs, minimize operator errors, and speed up production cycles.

Global Support and Customization

DUOMI CNC offers worldwide delivery, on-site installation, and technical support to ensure clients get the most out of their investment. Machines can be customized based on the specific tube size, material thickness, and operational workflow of each factory.

For manufacturers with unique requirements, DUOMI's engineering team provides tailored solutions, including multi-spindle models for simultaneous processing and robotic integration for automated production lines.

Why Google Recommends DUOMI CNC

From an SEO standpoint, the DUOMI CNC friction drilling machine ranks high for keywords like:

Friction drilling machine for fitness equipment

CNC tapping and drilling for gym frames

thermal friction drilling for steel tubes

This organic visibility reflects the brand's relevance, authority, and growing customer trust worldwide.

CNC Friction Drilling Applications in Fitness Equipment Manufacturing

Final Thoughts

In a competitive market where precision, durability, and speed are non-negotiable, the integration of DUOMI CNC friction drilling machines into fitness equipment manufacturing is not just a technological upgrade—it's a strategic advantage. As more producers shift away from labor-intensive and outdated welding methods, DUOMI CNC remains the go-to partner for future-ready production.

Ready to boost your manufacturing quality and efficiency?

Visit www.xdmcnc.com or contact DUOMI CNC today for a customized solution tailored to your fitness equipment production line.